Stainless Steel Inserts, Plastic Molding Inserts in Stainless Steel, Stainless Steel Molding Inserts, Stainless Steel Threaded Inserts, Metric Stainless Steel Inserts, 316 Stainless Steel Inserts

High Quality precision Stainless Steel inserts and Stainless Steel molding inserts, Threaded Stainless Steel Inserts of 304 and 316 grade Stainless Steel

Overview We are one of the leading manufacturers and exporters of Stainless Steel Inserts from India. We have been supplying Stainless Steel Moulding Inserts, Threaded Inserts, and Metric Inserts to the world market for many decades. Our high-precision Stainless Steel Inserts are engineered to provide superior strength, corrosion resistance, and long-term performance in diverse industrial environments. These inserts are widely used in plastic injection moulding, automotive, aerospace, electronics, telecom, and marine applications where durability, anti-corrosive properties, and reliable fastening are essential. Our inserts are produced in various metric and imperial thread sizes, ensuring compatibility with international standards like ISO, DIN, ASTM, BS, IS, and JIS.

Manufactured using CNC turning, Swiss-type sliding head machines, and automated thread-rolling units, our Stainless Steel Inserts are designed with tight tolerances and uniform threading profiles. Available in grades such as AISI 303, 304, 316, and 410, our inserts support a range of finishes including passivated, electro-polished, and dry film lubricated. Customization in design, knurling pattern, thread size, length, and packaging with private labelling is also available. With a turnaround time of 4–6 weeks and global shipping options, we ensure seamless supply for high-volume OEM and custom orders.

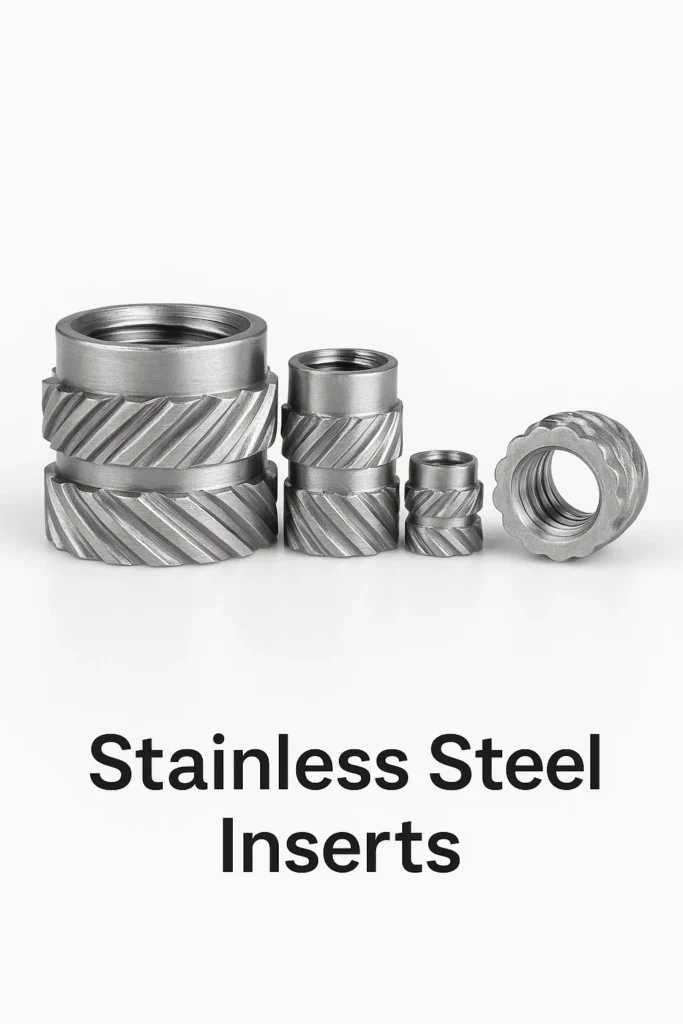

Stainless Steel Inserts Stainless Steel Inserts are precision metal components used to provide strong, wear-resistant threaded holes in softer base materials such as plastic, aluminium, or composite. These inserts are typically embedded into host materials via press-fit, ultrasonic, or heat staking methods. They deliver high pull-out resistance and torque strength, making them ideal for structural and load-bearing applications. Available in slotted, helical, and knurled configurations, our Stainless Steel Inserts meet stringent quality standards and are offered in custom and standard designs for aerospace, automotive, and medical devices.

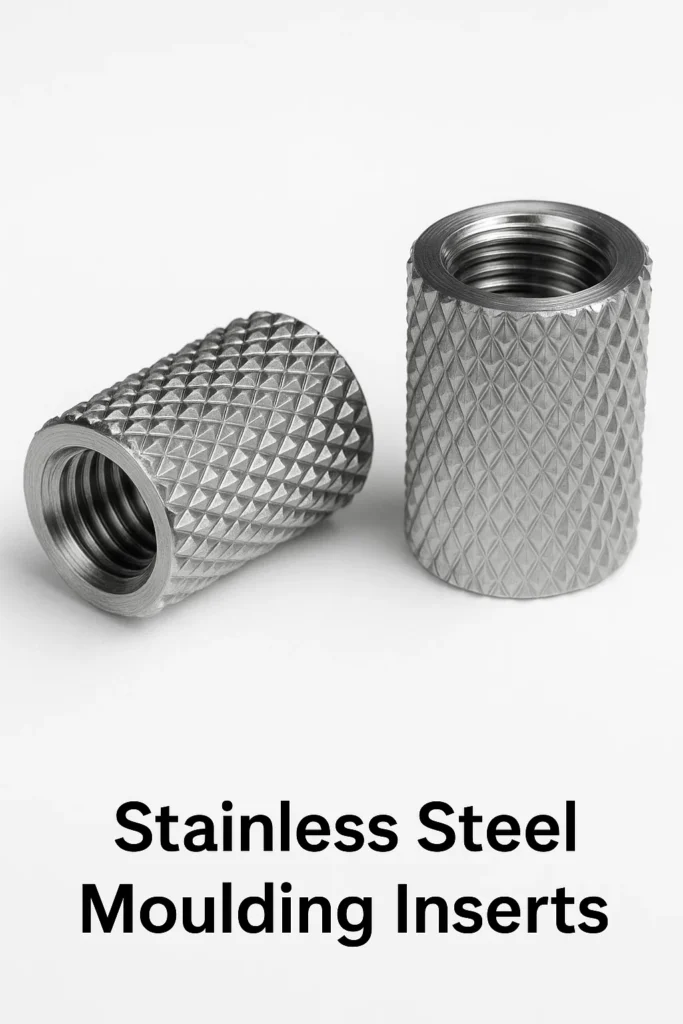

Plastic Moulding Inserts in Stainless Steel Plastic Moulding Inserts in Stainless Steel are specifically designed for direct mould-in applications during plastic injection moulding. These inserts are moulded into thermoplastic components during the forming process, resulting in a permanent, corrosion-resistant metal thread within the plastic structure. Our moulding inserts are manufactured with precision tolerances and feature knurled or undercut bodies to ensure superior mechanical anchorage. Commonly used in high-performance plastic enclosures, automotive dashboards, and electrical housings, these inserts are compatible with thermoplastics like ABS, Nylon, PBT, and PC.

Stainless Steel Moulding Inserts Stainless Steel Moulding Inserts are optimized for applications requiring enhanced bonding strength between metal and plastic. These inserts undergo specialized processes including cold-forming and threading to create high-strength, high-durability components. Designed for injection and compression moulding techniques, these inserts are commonly utilized in heavy-duty control modules, consumer electronics, and lighting systems. Available in symmetric and asymmetric geometries, they are tailored for precision fit and easy mould release.

Stainless Steel Threaded Inserts Stainless Steel Threaded Inserts provide permanent, high-strength threads in low-strength materials such as plastic, wood, or composite panels. Manufactured from AISI 303, 304, or 316 grades, these inserts are internally threaded and externally knurled or slotted to ensure secure fitment. Suitable for high-load assembly, these threaded inserts are used in aircraft interiors, control panels, electronics casings, and robotic assemblies. We offer a wide variety of thread standards including UNC, UNF, ISO Metric, and BSP to meet global compatibility.

Metric Stainless Steel Inserts Metric Stainless Steel Inserts are manufactured to ISO Metric thread specifications (M2 to M12) and are widely used across European and Asian markets. Our metric inserts are available in both coarse and fine thread pitches and can be customized in terms of overall length, outer diameter, and knurling depth. They are ideal for applications requiring consistent thread integrity and corrosion resistance, such as precision instrumentation, automotive sensors, and wearable electronics. All Metric Inserts conform to DIN and JIS standards.

316 Stainless Steel Inserts 316 Stainless Steel Inserts are high-grade inserts engineered for superior corrosion resistance, particularly in marine and chemical environments. Compliant with ASTM A276 and EN 10088-1, these inserts are chosen for their performance in saltwater, acidic, and high-humidity conditions. 316-grade Stainless Steel features added molybdenum content for improved pitting resistance, making it suitable for offshore, pharmaceutical, and food-grade applications. Our 316 inserts are available in machined and cold-formed variants with optional passivation.

Technical Specifications | Thread Sizes | M2–M12, UNC 4-40, 6-32, 8-32, 10-24, 1/4-20 etc. | | Grades | AISI 303, 304, 316, 410; ASTM A276, DIN 1.4301/1.4401 | | Insert Types | Press-in, Heat-set, Ultrasonic, Mould-in, Threaded | | Finishes | Natural, Passivated, Electropolished, Dry Film Lubricated | | Tolerances | ±0.03 mm or as per drawing | | Manufacturing | CNC Turning, Sliding Head Machining, Thread Rolling | | Turnaround Time | 4–6 Weeks |

Types of Inserts in Stainless Steel as well as Brass:

Round Inserts – Cylindrical, often knurled or grooved for retention.

Hexagonal Inserts – Provide anti-rotation properties.

Square Inserts – Offer higher torque resistance and stability.

Flanged Inserts – Include a flange to prevent over-insertion and enhance pull-out strength.

Heat-Set Inserts – Installed into thermoplastics using heat (e.g., ultrasonic or heated tip).

Ultrasonic Inserts – Embedded using ultrasonic vibrations for thermoplastics.

Press-Fit Inserts – Simply pushed into the plastic mold without heat.

Molded-In Inserts – Placed into the mold cavity before plastic injection, becoming encapsulated during molding.

Threaded Inserts

Provide durable internal threads in plastic parts.

Types: Male, Female, Self-Tapping.

Dowel/Locating Inserts

Used for alignment or precise positioning.

Electrical Inserts

Provide grounding or connectivity (e.g., Brass or Copper terminals).

Reinforcement Inserts

Strengthen the molded area for load-bearing purposes.

Brass Inserts – Common for excellent machinability and corrosion resistance.

Stainless Steel Inserts – Preferred where strength and corrosion resistance are critical.

Aluminum Inserts – Lightweight but not as durable as steel or brass.

Plastic Inserts – Occasionally used for light-duty applications or insulation.

Metric Inserts

Imperial (UNC/UNF) Inserts

Custom Thread Inserts (e.g., BSPT, NPT)

Why Choose Us? With over 30 years of global supply experience, we bring a strong advantage in product customization, prompt response, and scalable manufacturing. Our key differentiators include:

- Faster turnaround times

- Tight-tolerance machining

- Flexible MOQs and lead times

- Branded/Logo packaging

- Engineering & prototyping support

Customer Testimonial “Our procurement of Metric Stainless Steel Inserts from this supplier has been flawless. Their communication is timely, and they consistently meet our technical specifications and timelines. Outstanding quality and service.” — Rebecca S., Michigan, USA

Glossary of Terms

- Heat-set Insert: Insert installed using heat into thermoplastics for threaded reinforcement.

- Passivation: Chemical treatment that removes free iron and enhances corrosion resistance.

- Press-in Insert: Insert press-fitted into a preformed hole with interference fit.

- Thread Rolling: A process of forming threads without cutting, improving strength.

Related Terms Plastic Threaded Inserts, Metric Threaded Inserts, Moulded-In Inserts, Heat Staking Inserts, Knurled Metal Inserts for Plastic, High-Strength Stainless Inserts, Marine Grade Inserts

Call-to-Action To receive a custom quote or technical brochure, email us at sales@yourcompany.com or contact us via WhatsApp or phone at +91-XXXXXXXXXX. CAD files and physical samples are available on request.