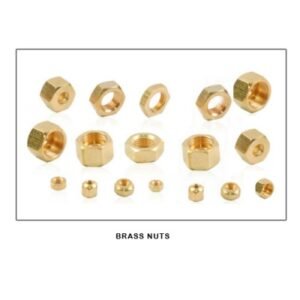

BRASS LOCK NUTS – PRECISION ENGINEERED FASTENING SOLUTIONS

HIGH-QUALITY BRASS LOCK NUTS FOR INDUSTRIAL AND COMMERCIAL APPLICATIONS

We are one of the leading manufacturers and exporters of Brass Lock Nuts, Brass Metric Lock Nuts, Brass Panel Nuts, and Brass Nickel Plated Lock Nuts from India. We have been supplying precision-engineered brass fastening components to the world market for many decades, establishing ourselves as a trusted partner for industries requiring superior quality threaded fasteners. Our comprehensive range of Brass Lock Nuts encompasses various specifications including UNC-UNF threads, Metric threads, and custom configurations designed to meet diverse industrial requirements. With state-of-the-art manufacturing facilities and a dedicated engineering team, we deliver brass lock nuts that exceed international quality standards while maintaining competitive pricing. Our production capabilities span from small batch custom orders to large-scale industrial supplies, ensuring consistent quality and timely delivery across all order volumes. The company’s commitment to excellence is reflected in our ISO-certified manufacturing processes and rigorous quality control measures that guarantee every Brass Lock Nut leaving our facility meets or exceeds customer specifications.

COMPREHENSIVE OVERVIEW OF BRASS LOCK NUTS

Brass Lock Nuts represent a critical category of threaded fastening components engineered to provide secure, vibration-resistant connections in mechanical assemblies. These specialized nuts are manufactured from high-grade Brass alloys, combining excellent corrosion resistance, superior electrical conductivity, and aesthetic appeal with functional durability. The fundamental design of Brass Lock Nuts incorporates self-locking mechanisms that prevent loosening under dynamic loads, vibration, and thermal cycling conditions. Our manufacturing expertise covers an extensive range of Brass Lock Nuts including hexagonal lock nuts, flange lock nuts, nylon insert lock nuts, all-metal lock nuts, and deformed thread lock nuts, each engineered for specific application requirements. The inherent properties of Brass make these lock nuts ideal for applications in plumbing systems, electrical equipment, marine hardware, automotive components, pneumatic systems, and instrumentation assemblies.

The versatility of Brass Lock Nuts extends across numerous thread standards including Metric threads (M1 through M100), Unified National Coarse (UNC), Unified National Fine (UNF), British Standard Whitworth (BSW), British Standard Fine (BSF), and British Association (BA) threads. Our production capabilities accommodate thread sizes ranging from miniature M1.6 fasteners used in precision instruments to heavy-duty M100 lock nuts employed in industrial machinery. Each Brass Lock Nut undergoes precision machining operations including thread rolling, thread cutting, hexagonal forming, and surface finishing to ensure dimensional accuracy within tight tolerances. The locking mechanism can be achieved through various methods including nylon inserts, deformed threads, serrated flanges, or dual-nut configurations, providing customers with multiple options based on their specific locking requirements and operating environments.

The material composition of our Brass Lock Nuts is carefully controlled to provide optimal mechanical properties including tensile strength ranging from 300 to 550 MPa, yield strength of 120 to 400 MPa, and elongation of 15% to 60% depending on the specific Brass alloy grade. Common Brass grades used in lock nut manufacturing include CuZn39Pb3, CuZn37, CuZn40, CZ121 (CW614N), CZ108 (CW617N), and free-cutting Brass varieties that facilitate high-speed machining operations. The excellent machinability of Brass alloys enables us to produce complex geometries and tight tolerances cost-effectively while maintaining high production rates. Surface treatments available for Brass Lock Nuts include natural brass finish, nickel plating, chrome plating, tin plating, and clear protective coatings that enhance corrosion resistance and provide specific aesthetic or functional requirements.

TYPES OF BRASS LOCK NUTS – DETAILED TECHNICAL SPECIFICATIONS

BRASS LOCK NUTS

Standard Brass Lock Nuts represent the foundational category of self-locking threaded fasteners manufactured from high-grade Brass alloys conforming to international material specifications. These nuts feature traditional hexagonal configurations with integrated locking mechanisms designed to resist rotational loosening under vibration, shock loads, and temperature variations. Our standard Brass Lock Nuts are available in thread sizes from M2 through M64 for metric specifications and #4-40 through 2-inch for unified thread standards. The locking action is typically achieved through nylon inserts positioned in the upper portion of the nut, creating interference fit with mating threads, or through deformed thread profiles that generate increased friction. Manufacturing tolerances for standard Brass Lock Nuts conform to ISO 2768-mH for general dimensions and ISO 965-2 for thread accuracy, ensuring proper fit with standard bolts and threaded studs. These lock nuts find extensive application in general mechanical assemblies, plumbing fixtures, electrical panel mounting, furniture hardware, and machinery where moderate locking performance is required. The hexagonal wrench flats are precision-machined to standard across-flat dimensions conforming to DIN 934 or ASME B18.2.2 specifications, facilitating easy installation with standard wrenches and socket tools.

BRASS METRIC LOCK NUTS

Brass Metric Lock Nuts are specifically engineered to comply with international metric thread standards including ISO 262, ISO 965, DIN 13, and related specifications governing metric coarse and fine thread profiles. These specialized lock nuts are manufactured with precise thread dimensions including major diameter, pitch diameter, minor diameter, and thread pitch conforming to tolerance classes 5H, 6H, or 7H depending on application requirements. Our Brass Metric Lock Nuts span the complete range of standard metric threads from M1.6 (1.6mm nominal diameter) used in micro-electronics and precision instruments through M100 (100mm nominal diameter) employed in heavy industrial equipment. The metric thread profile follows the standard 60-degree flank angle with specific root radius and crest configurations defined by international standards. Brass Metric Lock Nuts incorporate various locking mechanisms including polyamide (nylon 6 or nylon 6.6) inserts that maintain effectiveness across temperature ranges from -40°C to +120°C, metallic spring elements providing all-metal locking for high-temperature applications up to 250°C, or deformed thread sections creating mechanical interference. Manufacturing of Brass Metric Lock Nuts utilizes precision thread rolling dies or thread cutting operations on CNC automatic lathes, ensuring thread form accuracy within 6g tolerance class and positional accuracy within ±0.05mm for critical dimensions.

BRASS UNC-UNF LOCK NUTS

Brass UNC-UNF Lock Nuts are manufactured to conform with American unified thread standards specifically ASME B1.1 for Unified Inch Screw Threads covering both Unified National Coarse (UNC) and Unified National Fine (UNF) thread series. The UNC thread series provides coarse thread pitch suitable for general-purpose applications, rapid assembly, and use with lower strength materials, while UNF thread series offers finer pitch delivering superior locking performance, higher strength capacity, and better vibration resistance. Our Brass UNC-UNF Lock Nuts are available in standard imperial sizes ranging from #0-80 (0.060-inch nominal diameter, 80 threads per inch) through 4-inch diameter with corresponding thread pitches defined by unified thread standards. Thread accuracy conforms to tolerance classes 1B, 2B, or 3B with 2B being standard for most industrial applications, providing balanced fit with mating bolts. The hexagonal dimensions of Brass UNC-UNF Lock Nuts follow ASME B18.2.2 specifications for finished hex nuts, ensuring wrench flat dimensions match standard tooling. Locking mechanisms in Brass UNC-UNF Lock Nuts include prevailing torque features achieved through nylon pellet inserts, distorted threads, or spring-loaded components that maintain clamp load under dynamic loading conditions typical in automotive assemblies, marine equipment, aerospace ground support equipment, and industrial machinery manufactured to American standards.

BRASS PANEL NUTS

Brass Panel Nuts represent a specialized category of fastening hardware designed specifically for secure mounting of electrical panels, instrument housings, equipment enclosures, and decorative hardware to thin sheet materials including metal panels, plastic housings, and composite substrates. These distinctive nuts feature either cylindrical bodies with knurled external surfaces or hexagonal bodies combined with integrated flanges providing large bearing surfaces that distribute clamping forces across thin mounting substrates. The typical construction of Brass Panel Nuts includes fine-pitch threads (often M3×0.5, M4×0.5, M5×0.5 for metric, or #6-32, #8-32, #10-32 for unified threads) suitable for delicate electrical components and precision instrumentation. Installation of Brass Panel Nuts is accomplished through press-fitting into pre-punched circular or hexagonal panel cutouts, utilizing knurled external surfaces or locking tabs to prevent rotation during bolt tightening operations. Our Brass Panel Nuts are manufactured with precise body diameters matching standard panel punch sizes, flange thicknesses ranging from 1.0mm to 3.0mm, and overall heights from 4mm to 20mm depending on thread size and grip length requirements. Surface finishes include natural Brass, nickel plating for enhanced corrosion protection, and clear chromate coatings for aesthetic appearance. Brass Panel Nuts find primary applications in electrical switchgear assemblies, control panel construction, electronic equipment chassis mounting, telecommunications hardware, and decorative architectural hardware where both functional fastening and attractive appearance are required.

BRASS NICKEL PLATED LOCK NUTS

Brass Nickel Plated Lock Nuts combine the excellent mechanical properties and machinability of Brass base material with enhanced corrosion resistance, wear resistance, and aesthetic appearance provided by electroplated nickel surface coating. The nickel plating process deposits a uniform layer of metallic nickel typically ranging from 5 microns to 25 microns thickness across all exposed surfaces of the Brass Lock Nut, creating a barrier against atmospheric corrosion, chemical attack, and galvanic corrosion when assembled with dissimilar metals. Our Brass Nickel Plated Lock Nuts undergo multi-stage electroplating processes including surface preparation through degreasing and acid pickling, application of underlayers for improved adhesion, nickel deposition from sulfamate or Watts nickel baths, and post-treatment including chromate conversion or clear protective sealing. The nickel plating conforms to specifications including ASTM B689 for electrodeposited nickel coatings, ISO 4520 for chromate conversion coatings, and MIL-DTL-1501 for military applications requiring enhanced durability. Brass Nickel Plated Lock Nuts offer superior performance in marine environments, chemical processing equipment, food processing machinery, medical devices, and decorative applications where bright metallic appearance must be maintained. The nickel surface provides hardness values between 150-500 HV depending on plating parameters, significantly improving wear resistance compared to bare Brass. Thread dimensions are carefully controlled during plating operations to maintain proper fit with mating fasteners, typically accommodating plating thickness within 6H or 2B thread tolerance classes through pre-plating dimensional adjustments or post-plating thread chasing operations.

DIMENSIONAL SPECIFICATIONS – BRASS LOCK NUTS SIZE CHART

| A | B | C | |

|---|---|---|---|

| Thread Size | A/F (mm) | Thickness (mm) | |

| 1 | M3 | 5.5 | 2 |

| 2 | M4 | 7.0 | 2 |

| 3 | M5 | 8.0 | 2.5 |

| 4 | M6 | 10.0 | 3 |

| 5 | M8 | 13.0 | 4 |

| 6 | M10 | 17.0 | 5 |

| 7 | M12 | 19.0 | 6 |

| 8 | M16 | 24.0 | 8 |

| 9 | M20 | 30.0 | 10 |

| 10 | M24 | 36.0 | 12 |

| 11 | M30 | 46.0 | 14 |

UNC Brass Lock Nuts Size Charts

| Thread Size | A/F (mm) | A/F (inches) | Thickness (mm) | Thickness (inches) |

|---|---|---|---|---|

| #4-40 | 7.0 | 0.276 | 3.2 | 0.126 |

| #6-32 | 7.9 | 0.312 | 3.6 | 0.142 |

| #8-32 | 8.7 | 0.344 | 4.0 | 0.157 |

| #10-24 | 9.5 | 0.375 | 4.4 | 0.173 |

| #12-24 | 11.1 | 0.438 | 5.2 | 0.205 |

| 1/4″-20 | 11.1 | 0.438 | 5.6 | 0.220 |

| 5/16″-18 | 12.7 | 0.500 | 6.4 | 0.252 |

| 3/8″-16 | 14.3 | 0.562 | 7.1 | 0.280 |

| 7/16″-14 | 17.5 | 0.688 | 8.3 | 0.327 |

| 1/2″-13 | 19.1 | 0.750 | 9.5 | 0.375 |

Note: A/F = Across Flats (hex width). Dimensions are for standard brass lock nuts.

UNC Brass Lock Nuts (Medium to Large Sizes)

| Thread Size | A/F (mm) | A/F (inches) | Thickness (mm) | Thickness (inches) |

|---|---|---|---|---|

| 9/16″-12 | 22.2 | 0.875 | 10.3 | 0.406 |

| 5/8″-11 | 23.8 | 0.938 | 11.1 | 0.438 |

| 3/4″-10 | 28.6 | 1.125 | 13.5 | 0.531 |

| 7/8″-9 | 33.3 | 1.312 | 15.9 | 0.625 |

| 1″-8 | 38.1 | 1.500 | 17.5 | 0.688 |

| 1-1/8″-7 | 42.9 | 1.688 | 19.8 | 0.780 |

| 1-1/4″-7 | 47.6 | 1.875 | 22.2 | 0.875 |

| 1-3/8″-6 | 52.4 | 2.062 | 24.6 | 0.969 |

| 1-1/2″-6 | 57.2 | 2.250 | 27.0 | 1.062 |

MATERIAL GRADES AND INTERNATIONAL STANDARDS

Our Brass Lock Nuts are manufactured from premium quality Brass alloys conforming to multiple international material specifications ensuring global compatibility and performance consistency.

INTERNATIONAL MATERIAL STANDARDS:

INDIAN STANDARDS (IS): IS 319 Grade I and Grade II covering Brass rod and sections, IS 6912 for free-cutting Brass, IS 410 specifying Brass sheet and strip compositions including CuZn39Pb3 (equivalent to 60% Copper, 39% Zinc, 3% Lead), and IS 7452 for Brass fastener materials.

EUROPEAN STANDARDS (EN/DIN): EN 12164 designation CW614N representing free-cutting Brass with composition Cu 58%, Pb 3.0%, Zn remainder, commonly known as CuZn39Pb3 or CZ121, widely used for high-speed machining operations. EN 12163 designation CW617N (CZ108) containing 58-60% Copper, 2.5-3.5% Lead, balance Zinc, providing excellent machinability with superior corrosion resistance. DIN 17660 for Brass forgings and DIN 17662 for Brass fastener applications.

AMERICAN STANDARDS (ASTM/SAE): ASTM B16 covering free-cutting Brass rod, bar, and shapes with composition C36000 (61.5% Cu, 35.5% Zn, 3% Pb), ASTM B21 for naval Brass rod and bar, ASTM B124 covering Copper and Copper alloy forgings, and SAE J463 specification for wrought Copper and Copper alloy products.

BRITISH STANDARDS (BS): BS 2870 specifying Brass sheet, strip, and foil including CZ108 composition, BS 2874 for Brass rod and sections covering various Brass grades suitable for fastener manufacturing, and BS EN 12164 harmonized with European standards.

JAPANESE INDUSTRIAL STANDARDS (JIS): JIS H3250 for Copper and Copper alloy rods and bars including Brass grades C3604 (free-cutting Brass with 58-61% Cu, 2.5-3.7% Pb, remainder Zn), C3771 (forging Brass), and JIS B1052 for hexagonal nuts including lock nut specifications.

CHINESE NATIONAL STANDARDS (GB): GB/T 4423 covering Copper-Zinc alloy castings, GB/T 1176 for cast Copper and Copper alloys including Brass compositions, and GB/T 5231 specifying Brass plate, sheet, and strip with grades HPb59-1 and HPb62-3 commonly used in fastener production.

GERMAN STANDARDS (DIN): DIN 1709 for Brass forgings, DIN 17660 specifying forging alloys including CuZn39Pb2 and CuZn40Pb2, suitable for high-strength lock nut applications requiring enhanced mechanical properties.

MANUFACTURING PROCESSES AND PRODUCTION TECHNOLOGY

Brass Lock Nuts undergo sophisticated manufacturing processes combining traditional metalworking techniques with modern CNC automation to achieve precision dimensions and consistent quality. The production sequence begins with material procurement where certified Brass rods conforming to specified alloy compositions are received and verified through spectroscopic analysis to confirm chemical composition meets material standards. Raw Brass material is then cut to precise lengths using high-speed abrasive cutoff saws or automatic bar feeding systems integrated with production machinery.

PRIMARY MACHINING OPERATIONS are performed on CNC automatic lathes including Swiss-type screw machines (brands such as Citizen, Tsugami, Star, Tornos), multi-spindle automatic lathes for high-volume production, and CNC turning centers for larger diameter lock nuts. The turning operations include external hexagonal forming through rotary broaching tools or milling cutouts, bore drilling to establish internal thread minor diameter, chamfering operations on both entry and exit faces facilitating thread engagement, and precision facing of bearing surfaces ensuring consistent nut thickness dimensions. Thread forming is accomplished through either thread rolling using cylindrical dies that cold-form threads providing superior strength and surface finish, or precision thread cutting using single-point carbide threading tools or thread chasing dies for specialized thread profiles.

LOCKING FEATURE INTEGRATION varies based on lock nut design specification. Nylon insert lock nuts undergo additional operations where preformed nylon rings are pressed into circumferential grooves machined in the nut’s upper section, with nylon insert dimensions carefully controlled to provide specified prevailing torque values typically ranging from 20% to 70% of installation torque. All-metal lock nuts incorporate deformed thread sections created through precision punching operations that deliberately distort thread geometry in localized areas, or spring-loaded elements machined from Brass or stainless steel integrated into nut body. Flange lock nuts include additional milling operations creating serrated flanges with tooth profiles providing mechanical locking against joint surfaces.

SECONDARY OPERATIONS AND SURFACE TREATMENT encompass deburring processes using vibratory finishing equipment with ceramic media, achieving smooth edges and consistent surface texture across all components. Cleaning operations remove machining oils and residual debris through multi-stage ultrasonic cleaning systems using alkaline detergents followed by hot water rinsing. Surface finishing options include barrel tumbling for enhanced surface polish, electroplating operations (nickel, chrome, tin) performed in automated plating lines with precise current density control, and chromate conversion coatings providing corrosion protection while maintaining electrical conductivity.

QUALITY CONTROL INTEGRATION throughout manufacturing includes real-time dimensional verification using coordinate measuring machines (CMM), optical comparators, and digital micrometers checking critical dimensions including across-flat dimensions (±0.15mm tolerance), nut thickness (±0.10mm tolerance), thread pitch diameter verification using thread ring gauges or optical thread inspection systems, and prevailing torque testing for lock nuts with nylon inserts ensuring consistent locking performance.

MACHINERY AND EQUIPMENT USED IN PRODUCTION

Our state-of-the-art manufacturing facility houses advanced metalworking machinery specifically configured for high-precision Brass Lock Nut production. CNC SWISS-TYPE AUTOMATIC LATHES from manufacturers including Citizen Machinery (models L20, L32, M32, A20), Tsugami (SS20, SS32, BO326), Star Micronics (SV-20, SV-32), and Tornos (SwissNano, MultiSwiss) provide superior precision for small to medium diameter lock nuts up to 32mm, achieving positional accuracy within ±0.005mm and repeatability ensuring part-to-part dimensional variation below 0.01mm.

MULTI-SPINDLE AUTOMATIC SCREW MACHINES including Davenport, Wickman, and New Britain models enable high-volume production of standard Brass Lock Nuts with production rates exceeding 3000 pieces per hour depending on complexity. These machines feature multiple spindles working simultaneously on different production stages, optimizing cycle time and throughput. CNC TURNING CENTERS from brands including DMG Mori, Mazak, Okuma, and Haas handle larger diameter lock nuts from M36 through M100, equipped with live tooling allowing milling of hexagonal profiles, sub-spindles for complete part production in single setup, and bar feeders for lights-out manufacturing.

THREAD ROLLING MACHINES from manufacturers such as Reed-Rico, Kinefac, and Profiroll provide superior thread quality through cold-forming processes that strengthen thread profiles while achieving surface finishes below Ra 0.8 microns. Cylindrical thread rolling dies are precision-ground to specific thread forms ensuring accurate pitch diameter and thread angle conformance. HYDRAULIC PRESSES ranging from 5 tons to 150 tons capacity perform nylon insert installation, flange forming, and specialty nut configurations requiring compression forming operations.

SURFACE TREATMENT EQUIPMENT includes automated electroplating lines with rectifiers providing 1000-5000 ampere capacity for nickel plating operations, vibratory finishing systems with 500-liter capacity bowls for deburring and surface enhancement, and ultrasonic cleaning tanks (40 kHz frequency) ensuring thorough component cleanliness before plating or packaging operations.

QUALITY CONTROL INSTRUMENTATION encompasses coordinate measuring machines (Mitutoyo, Zeiss, Hexagon) with measuring accuracy ±0.002mm, optical comparators (Nikon, Mitutoyo) with 20x to 100x magnification for thread profile verification, digital torque testers (Mark-10, Shimpo) measuring prevailing torque from 0.01 to 100 Nm, thread gauges (go/no-go) conforming to ISO and ASME standards, and spectroscopy equipment (Oxford Instruments, Bruker) for material composition verification.

MATERIAL PROPERTIES OF BRASS LOCK NUTS

PROPERTY | CZ121 (CW614N) | CZ108 (CW617N) | C36000 (ASTM) | TEST METHOD

Copper Content | 58.0 – 59.0% | 58.0 – 60.0% | 60.0 – 63.0% | Spectroscopy Lead Content | 2.5 – 3.5% | 2.5 – 3.5% | 2.5 – 3.7% | ICP Analysis Zinc Content | Balance | Balance | Balance | Calculation Tensile Strength | 370 – 540 MPa | 380 – 540 MPa | 338 – 469 MPa | ISO 6892-1 Yield Strength (0.2%) | 120 – 330 MPa | 130 – 380 MPa | 124 – 310 MPa | ISO 6892-1 Elongation | 15 – 60% | 15 – 55% | 18 – 53% | ISO 6892-1 Hardness | 70 – 150 HV | 75 – 160 HV | 65 – 140 HB | ISO 6507-1 Density | 8.50 g/cm³ | 8.50 g/cm³ | 8.53 g/cm³ | ISO 3369 Electrical Conductivity | 26 – 28% IACS | 27 – 30% IACS | 26 – 28% IACS | ASTM B193 Thermal Conductivity | 120 W/m·K | 125 W/m·K | 115 W/m·K | ISO 22007-2 Coefficient of Thermal Expansion | 20.5 × 10⁻⁶/K | 20.0 × 10⁻⁶/K | 20.3 × 10⁻⁶/K | ASTM E228 Melting Point Range | 880 – 905°C | 885 – 900°C | 885 – 900°C | DSC Analysis Machinability Rating | 100% (reference) | 90% | 100% | Comparative Corrosion Resistance (Salt Spray) | >240 hours | >240 hours | >200 hours | ASTM B117

MANUFACTURING TOLERANCES AND QUALITY STANDARDS

Precision manufacturing of Brass Lock Nuts requires adherence to strict dimensional tolerances ensuring proper fit, function, and interchangeability across global supply chains. Our manufacturing tolerances conform to international standards including ISO 2768 for general tolerances, ISO 4759 for tolerances of fasteners, ISO 965 for metric screw threads, and ASME B1.1 for unified inch screw threads.

THREAD TOLERANCES: Metric threads are manufactured to tolerance class 6H (standard medium fit) with pitch diameter tolerances of ±0.036mm for M10 threads increasing proportionally for larger sizes. Unified threads conform to class 2B providing general-purpose fit with mating bolts. Fine-pitch threads may be produced to tighter 5H or 3B tolerances for precision assemblies requiring enhanced concentricity. Thread run-out measured perpendicular to thread axis is maintained within 0.08mm per 25mm of thread length ensuring proper load distribution across engaged threads.

HEXAGONAL DIMENSIONS: Across-flat dimensions (width across flats) conform to ISO 4759-1 tolerance class “medium” providing nominal dimension tolerances of ±0.15mm for sizes M5 through M12, increasing to ±0.25mm for M16 through M30, and ±0.35mm for sizes above M30. Across-corner dimensions maintain proportional tolerances ensuring wrench engagement without excessive play. Parallelism between opposite hexagonal faces is controlled within 0.10mm ensuring uniform torque distribution during installation.

THICKNESS TOLERANCES: Nut thickness (height) conforms to tolerance grade “A” per ISO 4759-1 maintaining ±0.10mm for sizes up to M16, ±0.15mm for M20 through M36, and ±0.20mm for larger sizes. Consistent thickness ensures proper thread engagement length meeting minimum requirements for full strength development typically requiring engagement of 1.0 to 1.5 times nominal diameter.

PERPENDICULARITY REQUIREMENTS: The bearing face (bottom surface contacting joint) maintains perpendicularity relative to thread axis within 0.15mm per 25mm diameter ensuring uniform load distribution across bolted joint interface. Top face perpendicularity relative to hexagonal sides is controlled within 0.20mm preventing cocking during wrench application.

SURFACE FINISH STANDARDS: Machined surfaces achieve roughness values Ra ≤ 3.2 micrometers on bearing faces, Ra ≤ 6.3 micrometers on hexagonal flats, and Ra ≤ 0.8 micrometers on rolled threads. Plated surfaces maintain uniform coating thickness within ±3 micrometers across all surfaces with adhesion meeting ASTM B571 tape test requirements.

PLATING AND SURFACE FINISHES AVAILABLE

NATURAL BRASS FINISH: Standard production Brass Lock Nuts feature natural golden yellow metallic appearance characteristic of Brass alloys, providing inherent corrosion resistance suitable for indoor applications and non-corrosive environments. Natural finish maintains electrical conductivity making these nuts ideal for grounding applications and electrical equipment. Surface protection can be enhanced through clear chromate conversion coatings (per ISO 4520 Type II) providing thin transparent barrier against tarnishing while preserving natural Brass appearance.

NICKEL PLATING (BRIGHT AND SATIN): Electroplated nickel coating deposited to thickness range 5-25 micrometers provides superior corrosion protection conforming to ASTM B689 Service Condition 2 (mild exposure) through Service Condition 4 (severe exposure). Bright nickel plating produces mirror-like reflective surface suitable for decorative applications, while satin nickel provides subdued matte finish preferred for industrial applications. Multi-layer nickel systems including copper undercoat (3-5 micrometers) + semi-bright nickel (8-12 micrometers) + bright nickel (2-3 micrometers) + micro-discontinuous chromium (0.3 micrometers) deliver enhanced corrosion resistance exceeding 500 hours neutral salt spray testing per ASTM B117.

TIN PLATING: Pure tin electroplating applied to thickness 5-15 micrometers provides excellent solderability for electronic applications, food-safe surface for food processing equipment contact components (conforming to FDA 21 CFR 175.300), and good corrosion protection in mildly corrosive environments. Tin plating maintains electrical conductivity while providing smooth silver-white appearance resistant to tarnishing.

CHROME PLATING (DECORATIVE AND HARD CHROME): Decorative chromium plating comprises multi-layer system including copper undercoat (10-20 micrometers) + nickel intermediate layer (15-25 micrometers) + chromium topcoat (0.3-0.8 micrometers) delivering mirror-bright finish with exceptional corrosion resistance. Hard chrome plating applied to thickness 5-50 micrometers provides wear-resistant surface with hardness 850-1000 HV suitable for high-friction applications, though less common for standard lock nuts.

ZINC-NICKEL ALLOY PLATING: Advanced corrosion-resistant coating containing 12-15% nickel in zinc matrix deposited to 8-12 micrometers thickness provides exceptional protection exceeding 1000 hours neutral salt spray testing with subsequent chromate sealing. Zinc-nickel plating offers superior performance compared to traditional zinc plating while maintaining RoHS and REACH compliance for European markets.

CLEAR PASSIVATION AND LACQUER: Transparent chromate conversion coatings (trivalent chromium per ISO 4520 Type II) or clear acrylic lacquer provide minimal protection against handling damage and short-term tarnish resistance while preserving natural Brass appearance. These economical finishes suit applications requiring attractive appearance without exposure to harsh environments.

INDUSTRIES AND APPLICATIONS UTILIZING BRASS LOCK NUTS

PLUMBING AND SANITARY SYSTEMS: Brass Lock Nuts serve critical roles in residential, commercial, and industrial plumbing installations securing faucet assemblies, valve stems, compression fittings, water heater connections, and pump mounting hardware. The corrosion resistance of Brass in water service combined with locking features prevents loosening from water hammer and thermal cycling during hot/cold water alternation. Brass Panel Nuts commonly mount plumbing fixtures to walls and countertops providing decorative appearance matching Brass trim components.

ELECTRICAL AND ELECTRONICS INDUSTRY: Brass Lock Nuts with excellent electrical conductivity function as grounding nuts, terminal connections, switchgear mounting hardware, circuit breaker assemblies, and electrical panel installations. Brass Panel Nuts secure electrical components, meters, and instrumentation to metal enclosures while maintaining electrical continuity. Nickel Plated Brass Lock Nuts provide EMI/RFI shielding effectiveness in electronic equipment housings while preventing galvanic corrosion when assembled with aluminum or steel panels.

MARINE AND SHIPBUILDING APPLICATIONS: The superior corrosion resistance of Brass in saltwater environments makes Brass Lock Nuts ideal for marine hardware including deck fittings, porthole assemblies, navigation equipment mounting, engine room piping systems, and galley equipment. Nickel Plated Brass Lock Nuts enhance corrosion protection for above-waterline applications exposed to salt spray and marine atmosphere meeting ASTM B633 corrosion resistance requirements.

AUTOMOTIVE AND TRANSPORTATION: Brass Lock Nuts find application in automotive electrical systems, instrument panel assemblies, climate control system connections, fuel system components (using lead-free Brass grades), and decorative trim fastening. Brass UNC-UNF Lock Nuts match American automotive fastener standards ensuring interchangeability with existing hardware. High vibration resistance prevents loosening in automotive service conditions.

HVAC AND REFRIGERATION EQUIPMENT: Brass Lock Nuts secure compressor components, valve assemblies, refrigerant line connections, condenser mounting hardware, and control system components in air conditioning and refrigeration systems. Thermal conductivity of Brass aids heat dissipation while corrosion resistance withstands exposure to condensation and refrigerant leakage.

PNEUMATIC AND HYDRAULIC SYSTEMS: Brass Metric Lock Nuts secure pneumatic fittings, air cylinder mounting, manifold assemblies, and instrumentation connections in compressed air systems. The pressure rating of properly tightened Brass Lock Nuts supports typical pneumatic system pressures up to 150 PSI (10 bar) with appropriate safety factors.

FURNITURE AND ARCHITECTURAL HARDWARE: Decorative Brass Lock Nuts including Nickel Plated and natural finish variations secure architectural trim, furniture hardware, decorative lighting fixtures, railing systems, and ornamental metalwork. The aesthetic appeal of Brass complements traditional and contemporary design elements while providing functional fastening.

MEDICAL AND LABORATORY EQUIPMENT: Brass Lock Nuts manufactured from lead-free Brass grades and Tin Plated Brass Lock Nuts provide biocompatible fastening solutions for medical equipment mounting, laboratory instrument assemblies, and pharmaceutical processing equipment. Compliance with FDA material requirements and ease of cleaning/sterilization make Brass suitable for healthcare applications.

MUSICAL INSTRUMENT MANUFACTURING: Brass Lock Nuts secure mechanical components in brass instruments, woodwind keywork, percussion hardware, and string instrument fittings. The material compatibility with instrument Brass alloys prevents galvanic corrosion while aesthetic appearance integrates with instrument finish.

TELECOMMUNICATIONS EQUIPMENT: Brass Panel Nuts mount telecommunications hardware, antenna systems, coaxial connectors, and equipment racks. Electrical conductivity provides grounding while Nickel Plated Brass finish matches standard telecommunications equipment aesthetics conforming to industry color standards.

TECHNICALS

HEXAGONAL LOCK NUT – TECHNICAL DRAWING (ISO Metric Type)

DIMENSIONAL REFERENCE:

- d = Thread Nominal Diameter (M3-M48)

- S = Width Across Flats (5.5mm – 75mm)

- e = Width Across Corners (minimum)

- H = Nut Height/Thickness (2.4mm – 48mm)

- m = Bearing Face Width

- da = Chamfer Diameter (both ends)

- P = Thread Pitch (0.4mm – 5.0mm)

- h = Nylon Insert Height (0.4H – 0.6H)

NOTES:

- All dimensions in millimeters unless otherwise specified

- Tolerances per ISO 4759-1 (Medium grade)

- Thread tolerance class: 6H per ISO 965-2

- Surface finish: Ra ≤ 3.2 µm on bearing face

- Material: CuZn39Pb3 (CW614N) or equivalent

- Hexagonal tolerance: ISO 4759-1 Medium grade

- Nylon insert: Polyamide 6 or Polyamide 6.6

- Perpendicularity: ≤ 0.15mm per 25mm diameter

STANDARD PRODUCTION LEAD TIME AND TURNAROUND

Our manufacturing facility maintains optimized production scheduling delivering reliable turnaround times balancing quality requirements with customer delivery expectations. STANDARD PRODUCTION LEAD TIME RANGES FROM 4 TO 6 WEEKS measured from confirmed purchase order receipt with advance payment or established credit terms through completed production, quality inspection, and readiness for shipment. This timeframe encompasses material procurement (1-2 weeks), production scheduling and setup (3-5 days), primary manufacturing operations (1-2 weeks), secondary operations including plating if specified (1 week), quality control inspection (2-3 days), and packaging preparation (1-2 days).

EXPEDITED PRODUCTION SERVICES are available for urgent requirements where production scheduling permits, potentially reducing lead time to 2-3 weeks with associated expedite charges typically 15-25% premium over standard pricing. Expedited orders receive priority scheduling, dedicated machine allocation, and accelerated processing through each production stage. Very urgent requirements may be accommodated through overtime manufacturing operations subject to current production load and material availability.

LARGE VOLUME ORDERS exceeding 100,000 pieces may require extended lead times of 6-8 weeks ensuring adequate material procurement, multiple production runs maintaining consistent quality, and coordination of packaging/shipping logistics. Phased delivery schedules can be arranged for large volume orders where customer storage capacity limits single shipment acceptance or production benefits from batch processing.

CUSTOM SPECIFICATIONS AND SPECIAL ORDERS including non-standard thread forms, unique plating requirements, special packaging, or modified dimensions typically add 1-2 weeks to standard lead time accommodating engineering review, custom tooling fabrication if required, process validation, and first article inspection procedures. Customer approval of first article samples may extend delivery schedule pending customer inspection and formal approval.

REPEAT ORDERS from established customers with previously manufactured specifications benefit from reduced lead times potentially 3-4 weeks leveraging existing tooling, validated production processes, and streamlined engineering review. Blanket purchase orders with scheduled releases enable further optimization through advance material procurement and production planning minimizing delivery delays.

PERFORMANCE CHARACTERISTICS AND TESTING PROTOCOLS

PREVAILING TORQUE PERFORMANCE: Brass Lock Nuts with nylon inserts maintain specified prevailing torque values ensuring consistent locking performance throughout service life. Testing conforms to ISO 2320 measuring torque required to advance nut along clean, dry threads at 10-15 RPM rotation speed. Typical prevailing torque values range from 20% to 70% of installation torque depending on thread size, nylon insert design, and temperature conditions. For M10 lock nuts, prevailing torque typically measures 3.5 – 8.0 Nm at room temperature (20-25°C). Performance is validated across temperature range -40°C to +120°C for nylon insert variants demonstrating consistent locking action throughout automotive and industrial service conditions.

REUSABILITY TESTING: Quality Brass Lock Nuts with nylon inserts typically support 5-10 installation/removal cycles maintaining adequate prevailing torque above minimum specification limits. Metal locking types (deformed thread, all-metal) may support 15-25 cycles depending on thread damage during installation. Testing evaluates prevailing torque degradation across multiple cycles identifying minimum torque threshold requiring component replacement.

PROOF LOAD AND TENSILE STRENGTH: Brass Lock Nuts manufactured from CZ121/CW614N material demonstrate proof load capacity approximately 80% of nominal tensile strength. For M10 nuts with property class comparable to steel grade 5, proof load approaches 16 kN with ultimate tensile load reaching 20 kN. Testing conforms to ISO 898-2 methodology adapted for Copper alloy materials. Brass Lock Nuts are not typically assigned standardized property classes like steel nuts but performance is verified through actual load testing ensuring adequate strength for intended applications.

SALT SPRAY CORROSION TESTING: Nickel Plated Brass Lock Nuts undergo neutral salt spray testing per ASTM B117 demonstrating corrosion resistance exceeding 240 hours (typical: 500+ hours for multi-layer nickel systems) before appearance of red rust or base metal corrosion. Natural Brass finish demonstrates excellent resistance to atmospheric corrosion with minimal surface tarnishing over extended exposure. Testing validates suitability for coastal, marine, and industrial environments where corrosive atmospheres challenge fastener integrity.

DIMENSIONAL STABILITY UNDER LOAD: Brass Lock Nuts maintain dimensional integrity under rated clamping loads demonstrating elastic deformation within acceptable limits ensuring full thread engagement recovery upon load removal. Permanent deformation testing applies loads equivalent to 150% proof load verifying threads remain functional for reassembly operations. Material properties including yield strength and elastic modulus ensure structural integrity throughout rated service conditions.

THREAD ENGAGEMENT AND STRIPPING STRENGTH: Properly manufactured Brass Lock Nuts provide thread engagement strength exceeding bolt tensile strength when minimum engagement length equals 1.0 to 1.5 times nominal diameter. Thread stripping tests demonstrate failure occurs in mating bolt threads rather than nut threads when proper engagement is achieved using CZ121 Brass material. Higher strength Brass alloys (CZ108/CW617N) provide enhanced stripping resistance for critical applications.

VIBRATION RESISTANCE TESTING: Brass Lock Nuts undergo dynamic vibration testing per DIN 65151 (Junker test) demonstrating superior resistance to rotational loosening compared to standard hex nuts. Nylon insert lock nuts maintain 95%+ of installation torque after 2000 vibration cycles under transverse load conditions. All-metal locking types demonstrate similar performance in high-temperature applications where nylon inserts lose effectiveness above 120°C.

COMPREHENSIVE QUESTION AND ANSWER SECTION

QUESTION 1: What are the primary advantages of using Brass Lock Nuts compared to steel lock nuts in plumbing applications?

Brass Lock Nuts offer several critical advantages for plumbing installations including superior corrosion resistance in water service eliminating rust contamination concerns associated with steel fasteners, excellent machinability enabling precise thread tolerances for leak-free compression fittings, attractive golden appearance matching plumbing fixture trim components, non-magnetic properties avoiding magnetic interference in specialized systems, and good thermal conductivity facilitating temperature equilibration in hot water systems. The lead content in traditional free-cutting Brass grades (now being phased out for potable water contact) enhanced machining performance, while modern lead-free Brass alloys maintain environmental compliance without sacrificing functional properties. Brass Metric Lock Nuts resist dezincification corrosion common in certain water chemistries particularly in coastal regions with elevated chloride levels.

QUESTION 2: Can Brass Lock Nuts with nylon inserts be used in high-temperature applications?

Brass Lock Nuts incorporating nylon inserts (typically Polyamide 6 or Polyamide 6.6 materials) maintain effective locking performance across temperature ranges from -40°C to approximately +120°C representing the maximum continuous service temperature for nylon materials. Beyond this threshold, nylon begins thermal degradation losing mechanical strength and locking effectiveness. For applications experiencing temperatures above 120°C including exhaust systems, engine components, or industrial heating equipment, all-metal Brass Lock Nuts utilizing deformed thread locking mechanisms or spring-loaded metallic elements provide suitable alternatives. These all-metal designs maintain locking function to temperatures approaching Brass annealing temperature around 250-300°C, though Brass material itself experiences strength degradation above 200°C suggesting consideration of higher-temperature alloys for extreme thermal environments.

QUESTION 3: What thread tolerance class should be specified for Brass Lock Nuts requiring high precision fit?

Thread tolerance selection for Brass Lock Nuts depends on application requirements balancing fit precision, assembly ease, and locking performance. Standard industrial applications typically specify ISO 965-2 tolerance class 6H for metric threads or ASME B1.1 class 2B for unified threads providing medium fit with adequate clearance for assembly while maintaining proper locking interference. Precision instruments and equipment requiring minimized backlash benefit from tolerance class 5H (metric) or class 3B (unified) offering tighter pitch diameter tolerances improving positional accuracy and thread engagement uniformity. Very tight tolerances (4H or tighter) generally prove impractical for Brass Lock Nuts as locking mechanisms inherently introduce thread interference potentially preventing assembly. Conversely, loose fit tolerance class 7H accommodates plated Brass Lock Nuts where coating thickness reduces effective clearance requiring compensation through enlarged nut thread dimensions.

QUESTION 4: How does the lead content in traditional Brass alloys affect environmental compliance and product specifications?

Traditional free-cutting Brass alloys including CZ121 (CW614N) and C36000 contain 2.5-3.5% lead enhancing machinability during high-speed production operations by facilitating chip breaking and reducing tool wear. However, environmental and health regulations including the Safe Drinking Water Act (USA), California Proposition 65, and European REACH Directive restrict lead content in materials contacting potable water. Consequently, manufacturers now offer lead-free Brass alternatives including silicon Brass (Eco-Brass containing bismuth), Copper alloys with reduced lead content below 0.25%, and specially formulated Brass grades meeting NSF/ANSI 61 certification for drinking water system components. Brass Lock Nuts for plumbing applications increasingly specify lead-free compositions while general industrial, electrical, and mechanical applications continue utilizing traditional Brass grades where lead restrictions do not apply. Material certification documentation accompanies lead-free Brass Lock Nuts confirming compliance with applicable regulations.

QUESTION 5: What is the recommended installation torque for Brass Metric Lock Nuts?

Installation torque for Brass Metric Lock Nuts varies with thread size, lubrication condition, and assembly configuration. General guidance follows torque values approximately 60-70% of steel fastener equivalents accounting for lower mechanical strength of Brass materials. Representative torque values include: M3 = 0.8-1.2 Nm, M4 = 1.5-2.0 Nm, M5 = 2.5-3.5 Nm, M6 = 4.0-6.0 Nm, M8 = 10-14 Nm, M10 = 18-25 Nm, M12 = 30-40 Nm, M16 = 60-85 Nm, M20 = 110-150 Nm. These values assume dry assembly conditions (no lubricant) with nuts threaded onto Brass or steel bolts. Application of lubricants reduces friction requiring torque reduction of 15-25% preventing over-torquing leading to thread stripping. Brass UNC-UNF Lock Nuts follow similar torque guidelines converted to unified thread sizes. Critical assemblies benefit from torque verification using calibrated torque wrenches and potentially thread locking compounds enhancing vibration resistance in applications where prevailing torque alone proves insufficient.

QUESTION 6: Are Brass Panel Nuts suitable for outdoor applications exposed to weather?

Brass Panel Nuts demonstrate good outdoor durability in temperate climates experiencing moderate atmospheric exposure, though surface treatment significantly influences long-term appearance and corrosion resistance. Natural Brass finish develops protective patina (tarnish layer) in atmospheric service maintaining structural integrity while experiencing aesthetic darkening over time. Nickel Plated Brass Panel Nuts provide superior outdoor performance resisting corrosion and maintaining bright metallic appearance through multi-year exposure in coastal and industrial atmospheres. For architectural applications requiring sustained appearance, specification of heavy nickel plating (15-25 micrometers) with chromate sealing or clear coating delivers optimal protection. Installation practices should ensure drainage avoiding water accumulation in nut recesses potentially accelerating corrosion. Marine environments and direct seawater splash exposure may challenge even plated Brass, suggesting consideration of marine-grade materials (naval Brass, Bronze) for most demanding conditions.

QUESTION 7: What are the key differences between Brass Lock Nuts and Brass Jam Nuts?

Brass Lock Nuts and jam nuts serve distinct fastening functions despite both being hexagonal threaded components manufactured from Brass materials. Brass Lock Nuts incorporate specific locking mechanisms (nylon inserts, deformed threads, spring elements) preventing rotational loosening under vibration and dynamic loading, typically feature standard height (approximately 0.8 times nominal diameter), and are designed as primary fastening components providing full thread engagement strength. Jam nuts conversely represent thin-profile nuts (height approximately 0.5 times nominal diameter or less) lacking inherent locking features, functioning as secondary lock devices threaded against primary nuts creating frictional resistance preventing loosening. Jam nut applications typically involve double-nut configurations where full-height primary nut develops required clamping force while thin jam nut torqued against primary nut provides locking action. Brass Lock Nuts offer single-component locking solution simplifying assembly while jam nuts provide economical locking alternative for non-critical applications accepting increased assembly time and component count.

QUESTION 8: Can Brass Lock Nuts be welded or soldered to other components?

Brass materials demonstrate good solderability enabling joining of Brass Lock Nuts to other Brass, Copper, or Bronze components using soft solders (tin-lead or lead-free tin-silver-copper alloys) or silver brazing alloys. Soldering processes require surface preparation including degreasing and mechanical or chemical cleaning removing oxides, application of suitable flux (zinc chloride-based for Brass), heating to solder melting temperature (approximately 190-220°C for soft solders, 600-800°C for silver brazing), and controlled cooling avoiding thermal shock. Nickel Plated Brass Lock Nuts require plating removal in joint area as nickel interferes with solder wetting. Welding Brass components presents challenges due to zinc volatilization at welding temperatures creating porous welds and toxic fumes, though specialized processes including gas tungsten arc welding (GTAW) with filler metals and careful heat control can join Brass components. Generally, mechanical fastening or soldering/brazing prove more practical for Brass Lock Nut attachment compared to fusion welding. Thread-locking compounds provide alternative method securing Brass Lock Nuts without heat application potentially affecting material properties.

QUESTION 9: What quality certifications should be requested when purchasing Brass Lock Nuts for critical applications?

Critical applications requiring documented material traceability and performance verification benefit from comprehensive quality certifications including Material Test Certificates (MTC) per EN 10204 Type 3.1 documenting chemical composition analysis, mechanical property testing results, and material grade conformance certified by manufacturer’s quality department. Certificate of Conformance (CoC) verifies manufactured Brass Lock Nuts comply with specified dimensional standards (ISO, ASME, DIN), thread tolerances, and plating requirements where applicable. First Article Inspection Reports (FAIR) per AS9102 provide dimensional verification of initial production samples validating manufacturing process capability before full production authorization. RoHS Declaration of Conformance certifies compliance with Directive 2011/65/EU restricting hazardous substances in electrical and electronic equipment. REACH Compliance Documentation confirms Brass Lock Nut materials comply with European chemical substance regulations. Salt Spray Test Reports per ASTM B117 verify corrosion resistance performance for plated components. Dimensional Inspection Reports including thread gauge verification using certified gauges demonstrate dimensional conformance. Suppliers maintaining ISO 9001:2015 quality management system certification provide systematic quality assurance throughout manufacturing processes.

QUESTION 10: How do you select between Brass Metric Lock Nuts and Brass UNC-UNF Lock Nuts for international projects?

Thread system selection for international projects balances several considerations including regional standards predominance, existing equipment compatibility, maintenance spare parts availability, and engineering specifications. Brass Metric Lock Nuts follow ISO metric thread standards universally adopted across Europe, Asia, Australia, and increasingly globally as primary fastener specification system. Metric threads offer rationalized sizing progression (M1.6, M2, M2.5, M3, etc.) with standardized pitch values simplifying inventory management. Brass UNC-UNF Lock Nuts conform to American unified thread standards remaining prevalent in United States, Canada, and equipment manufactured to American standards including many automotive, aerospace, and oil/gas industry applications. Unified threads use fractional inch sizing (#4-40, #6-32, 1/4-20, etc.) with coarse (UNC) and fine (UNF) pitch series. International projects involving American-manufactured equipment or exporting to North American markets typically specify Brass UNC-UNF Lock Nuts ensuring direct interchangeability. Projects in European, Asian, or Australian markets generally specify metric threads. Mixed installations may require dual inventory or adapter bushings enabling metric-to-unified thread conversion.

QUESTION 11: What factors affect the prevailing torque values in nylon insert Brass Lock Nuts?

Multiple variables influence prevailing torque performance of nylon insert Brass Lock Nuts requiring understanding for proper application specification. Nylon insert material properties including hardness, compression modulus, and thermal stability determine baseline locking force generation with Polyamide 6 and Polyamide 6.6 being standard materials providing optimal balance of locking performance and durability. Insert geometry encompasses height (typically 40-60% of nut height), inner diameter interference (designed for specific thread size), and retention groove design securing insert against rotation or extrusion. Thread lubrication significantly impacts prevailing torque with dry threads generating 40-60% higher prevailing torque than lubricated assemblies, necessitating torque specification clarity regarding lubrication state. Temperature affects nylon properties with increasing temperature reducing prevailing torque approximately 10% per 25°C temperature rise from room temperature toward nylon’s 120°C service limit. Thread condition including cleanliness, damage, and plating affects friction with thread contamination, corrosion, or damage potentially increasing or erratically varying prevailing torque. Installation speed influences measured values with rapid installation generating higher apparent prevailing torque due to friction heat buildup temporarily softening nylon. Reuse history degrades prevailing torque with each installation cycle wearing nylon and embedding thread impressions requiring replacement after 5-10 cycles depending on application severity.

QUESTION 12: Are there size limitations for manufacturing custom Brass Lock Nuts?

Brass Lock Nut manufacturing spans extensive size ranges though practical limitations exist at extreme dimensions. Minimum sizes typically begin at M1.6 or #0-80 (1.6mm nominal diameter) constrained by machining capability, nylon insert miniaturization, and thread forming tooling availability. Smaller sizes prove challenging regarding insert retention and handling during production though specialized micro-fastener manufacturers produce M1 and smaller sizes for electronics and precision instruments. Maximum sizes extend to M100 or 4-inch diameter for standard hexagonal lock nuts limited by material availability in rod/bar form, machine capacity for large component turning and hexagonal forming, and nylon insert sourcing for large diameter applications. Larger sizes frequently employ all-metal locking designs as nylon insert dimensions become impractical. Custom specifications including non-standard thread pitches, special hexagon dimensions, unique nut heights, or unusual locking mechanisms are readily accommodated within typical size ranges though may require custom tooling fabrication, engineering analysis validating design feasibility, and minimum order quantities justifying setup costs. Prototype and development quantities support design validation before committing to production tooling investment.

QUESTION 13: How does the electrical conductivity of Brass Lock Nuts benefit grounding applications?

Brass materials demonstrate excellent electrical conductivity typically 26-28% IACS (International Annealed Copper Standard) significantly superior to steel fasteners (3-15% IACS depending on alloy) making Brass Lock Nuts advantageous for electrical grounding, bonding, and current-carrying applications. The high conductivity ensures minimal voltage drop across threaded connections maintaining electrical continuity in grounding systems, enables current carrying capacity supporting circuit protection schemes, and provides low-resistance paths dissipating static electricity buildup protecting personnel and equipment. Brass Lock Nuts securing electrical busbars, grounding conductors to equipment enclosures, bonding jumpers bridging painted surfaces, and terminal connections benefit from this conductivity combined with corrosion resistance maintaining long-term connection integrity. The natural oxide formation on Brass surfaces (unlike aluminum requiring special contact compounds) maintains reasonable conductivity without extensive surface preparation. Nickel Plated Brass Lock Nuts retain good electrical performance though nickel layer (being ferromagnetic and lower conductivity) slightly increases contact resistance compared to bare Brass, remaining acceptable for most grounding applications. Proper torque application ensuring metal-to-metal contact between Brass Lock Nut bearing face and mating surface optimizes conductivity, with conductive compounds or star washers enhancing performance in critical applications.

QUESTION 14: What maintenance practices extend the service life of Brass Lock Nuts in field installations?

Brass Lock Nuts benefit from systematic maintenance practices maximizing functional service life in field applications. Periodic inspection examines visible condition checking for corrosion, mechanical damage, loose installation, or thread damage indicating need for replacement. Cleaning removes accumulated dirt, debris, and corrosion products using mild detergent solutions or specific Brass cleaners avoiding abrasive materials damaging surface finish or plating. Corrosion protection in harsh environments applies protective coatings including clear lacquers or corrosion inhibitors (especially for natural Brass finishes exposed to atmospheric moisture) preventing accelerated tarnishing and material loss. Retorquing during scheduled maintenance intervals verifies installation torque remains within specification, though excessive retorquing of nylon insert lock nuts accelerates wear requiring eventual replacement. Thread lubrication during reassembly using appropriate anti-seize compounds or thread lubricants prevents galling, reduces installation torque requirements, and facilitates future disassembly though may alter prevailing torque characteristics. Replacement schedules establish proactive component replacement intervals for critical applications, typically after 5-10 installation cycles for nylon insert Brass Lock Nuts before prevailing torque degrades below acceptable limits. Documentation maintains installation records tracking torque values, dates, and component replacement history supporting reliability analysis and preventive maintenance optimization.

QUESTION 15: Can Brass Lock Nuts be used with stainless steel bolts without galvanic corrosion concerns?

Combining Brass Lock Nuts with stainless steel bolts creates bimetallic couple with potential for galvanic corrosion requiring evaluation of environmental exposure conditions. The galvanic series positions Brass (composed primarily of Copper and Zinc) as more anodic (less noble) than stainless steel alloys meaning Brass becomes preferential anode in corrosive electrolyte exposure potentially experiencing accelerated corrosion. However, practical considerations often permit this combination successfully. In dry environments or indoor applications lacking continuous moisture, galvanic corrosion remains negligible as electrolyte absence prevents current flow between dissimilar metals. Outdoor applications in temperate climates with occasional moisture exposure generally demonstrate acceptable performance over multi-year service life, particularly with periodic drying intervals limiting electrolyte presence. Marine environments, chemical exposure, or continuous immersion present highest risk scenarios potentially accelerating Brass corrosion, suggesting consideration of protective measures including non-metallic washers electrically isolating dissimilar metals, application of corrosion-resistant coatings (Nickel Plated Brass Lock Nuts reducing exposed Brass area), use of corrosion inhibitors, or material substitution selecting compatible metal combinations (stainless nuts with stainless bolts, Brass nuts with Brass bolts). The relatively small size differential between Brass Lock Nut (anode) and stainless bolt (cathode) moderates corrosion intensity compared to configurations with small anode/large cathode area ratios producing severe localized attack.

WHY CHOOSE OUR BRASS LOCK NUTS – UNIQUE VALUE PROPOSITION

Our company distinguishes itself as a premier manufacturer and exporter of Brass Lock Nuts, Brass Metric Lock Nuts, Brass Panel Nuts, and specialty brass fastening components through comprehensive capabilities and customer-focused services refined over three decades of international business operations. The combination of advanced manufacturing technology, metallurgical expertise, flexible production systems, and dedicated customer support positions our organization as the preferred supplier for customers requiring reliable quality, responsive service, and competitive value.

GLOBAL MANUFACTURING EXPERIENCE SPANNING THREE DECADES positions our engineering and production teams with deep knowledge of international standards, material specifications, quality requirements, and application-specific demands across diverse industries worldwide. This experience base enables rapid understanding of customer requirements, anticipation of potential challenges, and proactive solutions preventing quality issues or delivery delays. Our long-standing relationships with global customers from North America, Europe, Australia, and Asia demonstrate sustained satisfaction with product quality and service reliability.

FASTER TURNAROUND TIMES compared to typical industry standards represent a core competitive advantage achieved through optimized production scheduling, adequate raw material inventory, efficient manufacturing processes, and streamlined quality control procedures. Standard delivery of 4-6 weeks for most Brass Lock Nut specifications, with expedited options potentially reducing timelines to 2-3 weeks, ensures customers receive components when needed supporting project schedules and inventory management objectives. Rush order accommodation prevents costly project delays when unexpected requirements arise.

ENGINEERING SUPPORT AND TECHNICAL CONSULTATION differentiates our service beyond commodity fastener supply. Our qualified engineering team collaborates with customers during specification development, reviews technical drawings identifying potential manufacturing challenges or design improvements enhancing functionality while reducing cost, suggests material grade alternatives optimizing performance or economy, and validates thread specifications ensuring compatibility with mating components. This technical interaction adds value particularly for custom applications, new product development, or complex assemblies where fastener selection impacts overall system performance.

CUSTOMIZATION FLEXIBILITY accommodates diverse customer requirements beyond standard catalog specifications. Our production capabilities support non-standard thread forms, unique hexagonal dimensions, special nut heights, alternative plating finishes, custom packaging configurations, and hybrid designs combining features from multiple standard types. Reasonable minimum order quantities enable prototype and development programs without excessive inventory commitment, while production scalability supports growth from initial samples through high-volume manufacturing.

QUALITY ASSURANCE AND DOCUMENTATION meets stringent international standards through ISO 9001:2015 certified quality management systems, comprehensive testing protocols, calibrated measurement equipment traceable to national standards, and detailed documentation including material test certificates, dimensional inspection reports, and compliance certifications. This systematic quality approach ensures consistent product conformance, reduces customer receiving inspection requirements, and supports critical applications demanding verified performance.

COMPETITIVE PRICING STRUCTURE reflects efficient manufacturing operations, direct factory pricing eliminating intermediate markups, economies of scale from high production volumes, and strategic raw material procurement. Transparent pricing communication, volume discounts for large orders, and long-term supply agreement flexibility provide cost predictability supporting customer budgeting processes.

RESPONSIVE CUSTOMER COMMUNICATION ensures inquiries receive prompt attention, quotations are prepared quickly and accurately, order status updates are proactively provided, and concerns are addressed efficiently. Multiple communication channels including email, phone, WhatsApp, and video conferencing accommodate customer preferences and time zone differences facilitating smooth international business transactions. Dedicated account management for major customers provides consistent point-of-contact relationship continuity.

CUSTOM PACKAGING SOLUTIONS support customer operational requirements including private labeling with customer logos and part numbers, specialized packaging preventing damage during shipping and handling, customized quantities per package matching assembly line consumption rates, barcoding for automated inventory management, and export packaging meeting international shipping standards for container freight or air cargo.

BROAD MATERIAL AND FINISH OPTIONS spanning multiple Brass alloy grades, plating alternatives including nickel, tin, chrome, and zinc-nickel, and natural finishes with protective coatings enable precise material specification matching application environment and aesthetic requirements. Lead-free Brass compliance for potable water applications, RoHS/REACH conformance for European markets, and specialty alloys for demanding performance conditions demonstrate material expertise and supply chain flexibility.

PACKAGING, SHIPPING, AND EXPORT SERVICES

Brass Lock Nuts require careful packaging protecting against mechanical damage, corrosion during storage and transit, and ensuring components arrive in ready-to-use condition. Our packaging systems are designed specifically for fastener logistics accommodating both domestic distribution and international export requirements.

PRIMARY PACKAGING utilizes polyethylene bags with corrosion inhibitor (VCI) protecting Brass surfaces from atmospheric moisture and contamination during storage. Package quantities are configured to customer specifications ranging from small quantities (25-100 pieces) for maintenance supplies through bulk packages (1000-5000 pieces) for production consumption. Carton labeling clearly identifies part number, thread size, material grade, quantity, and manufacturing date facilitating inventory management and traceability.

SECONDARY PACKAGING employs corrugated cartons or wooden crates depending on shipment size and handling requirements. Cartons are reinforced for stacking during warehouse storage and container loading, with internal dividers or foam inserts preventing package shifting during transit. Weight per carton is controlled (typically maximum 15-20 kg) facilitating manual handling while optimizing cubic utilization.

EXPORT PACKAGING for ocean freight meets international shipping container standards including moisture barrier packaging, desiccant packets controlling humidity, external marking conforming to import regulations including country of origin labeling, and documentation packages including commercial invoice, packing list, certificate of origin, and material certificates sealed in waterproof envelopes attached to shipment exterior.

CUSTOM LABELING SERVICES apply customer-specified labels including company logos, custom part numbers, barcode symbology (Code 39, Code 128, QR codes), and specific text formatting meeting customer warehouse management system requirements. Labels can be applied to individual packages or carton exteriors depending on customer inventory control processes.

SHIPPING METHODS accommodate various customer logistics preferences including ocean freight for large volume shipments providing most economical transportation (typical transit time India to USA: 18-25 days, Europe: 20-30 days), air freight for urgent requirements delivering in 5-7 days though at premium cost, courier services (DHL, FedEx, UPS) suitable for samples and small shipments with door-to-door tracking, and consolidated shipping combining multiple orders optimizing freight costs for regular customers with steady requirements.

EXPORT DOCUMENTATION prepared by our experienced export department includes commercial invoices with accurate HS code classification (typically 7415.33.00 for Brass screws, bolts, nuts, and similar articles), packing lists itemizing carton contents and gross/net weights, certificates of origin (preferential or non-preferential depending on trade agreements), material test certificates when required, and fumigation certificates for wooden packaging when mandated by import country regulations.

FREIGHT FORWARDING COORDINATION through established relationships with international freight forwarders ensures competitive shipping rates, reliable transit times, comprehensive cargo insurance options, customs clearance facilitation, and last-mile delivery coordination to customer facilities. We handle export logistics allowing customers to focus on their core operations while receiving timely deliveries.

INCOTERMS FLEXIBILITY supports various international trade terms including FOB (Free On Board) where customer arranges ocean freight, CIF (Cost Insurance Freight) including freight and insurance to destination port, DDU (Delivered Duty Unpaid) with delivery to customer location excluding import duties, and DDP (Delivered Duty Paid) providing fully delivered pricing. Clear Incoterm specification prevents misunderstanding regarding cost responsibility and logistics coordination.

INTERNATIONAL STANDARDS AND SPECIFICATIONS COMPLIANCE

Our Brass Lock Nuts manufacturing processes conform to comprehensive international standards ensuring global interchangeability and regulatory compliance:

INDIAN STANDARDS: IS 1367 (Hexagon Nuts), IS 5374 (Lock Nuts), IS 6639 (Metric Nuts), IS 319 (Brass Rod and Sections), IS 6623 (Electroplated Coatings)

INTERNATIONAL ORGANIZATION FOR STANDARDIZATION: ISO 2320 (Prevailing Torque Type Nuts), ISO 7042 (Prevailing Torque Type All-Metal Hexagon Nuts), ISO 7044 (Prevailing Torque Type Hexagon Nuts with Non-Metallic Insert), ISO 4759-1 (Tolerances for Fasteners), ISO 965-2 (Metric Screw Threads Tolerances), ISO 4032 (Hexagon Nuts Style 1), ISO 8673 (Hexagon Nuts Style 2), ISO 2768 (General Tolerances)

AMERICAN STANDARDS: ASME B18.2.2 (Square and Hex Nuts), ASME B1.1 (Unified Inch Screw Threads), ASME B18.16.6 (Prevailing-Torque Type Nuts), ASTM B16 (Free-Cutting Brass Rod), ASTM B21 (Naval Brass Rod), ASTM B99 (Copper Silicon Alloy Rod), ASTM B117 (Salt Spray Testing), ASTM B633 (Electrodeposited Zinc Coatings), ASTM B689 (Electrodeposited Nickel Coatings)

GERMAN STANDARDS (DIN): DIN 934 (Hexagon Nuts), DIN 985 (Prevailing Torque Type Hexagon Nuts with Non-Metallic Insert), DIN 980 (All-Metal Hexagon Lock Nuts), DIN 13 (Metric Screw Threads), DIN 17660 (Brass Forgings), DIN 50961 (Electroplated Coatings)

BRITISH STANDARDS: BS 1768 (Thin Hexagon Nuts), BS 2870 (Brass Sheet and Strip), BS 2874 (Brass Rod and Sections), BS EN 12164 (Free-Cutting Brass)

JAPANESE INDUSTRIAL STANDARDS: JIS B1052 (Hexagon Nuts), JIS B1056 (Hexagon Lock Nuts), JIS H3250 (Brass Rods and Bars), JIS H8610 (Testing Methods for Electroplated Coatings)

EUROPEAN STANDARDS: EN 12164 (Free-Cutting Brass), EN 12163 (Brass for General Purposes), EN ISO 4032 (Hexagon Nuts Style 1), EN ISO 7042 (All-Metal Lock Nuts)

MILITARY SPECIFICATIONS: MIL-DTL-1222 (Lock Nuts), MIL-N-25027 (Nuts Self-Locking), MIL-DTL-1501 (Nickel Plating)

CUSTOMER TESTIMONIALS

JAMES MITCHELL, PROCUREMENT MANAGER – HOUSTON, TEXAS, USA

“We have been sourcing Brass Lock Nuts and Brass Panel Nuts from this manufacturer for the past eight years, and their consistency in quality and delivery has been absolutely exceptional. Initially, we were hesitant switching from our domestic supplier, but the combination of competitive pricing, superior product quality, and outstanding technical support made the transition seamless. Their engineering team worked closely with us to optimize our fastener specifications, actually suggesting design modifications that reduced our assembly time by 15% while improving joint reliability. The Nickel Plated Brass Lock Nuts we use in our marine equipment line have performed flawlessly in harsh salt spray environments, exceeding our corrosion resistance expectations. Their 4-6 week turnaround is reliable, and they’ve accommodated our rush orders multiple times without compromising quality. Communication has been excellent despite the time zone differences – responses to technical queries arrive within hours, and their account manager proactively updates us on order status. The custom packaging with our part numbers printed on each package has streamlined our receiving process significantly. Simply put, this is the gold standard for international supplier partnerships.”

SARAH THOMPSON, ENGINEERING DIRECTOR – ., BIRMINGHAM, UNITED KINGDOM

“As a manufacturer of high-precision measurement instruments and scientific equipment, we demand fasteners meeting exacting specifications with zero tolerance for quality variations. This company has consistently delivered Brass Metric Lock Nuts meeting our stringent requirements for the past twelve years. Their understanding of tight tolerances, proper material selection, and appropriate surface finishes demonstrates deep metallurgical knowledge rare among fastener suppliers. We particularly value their flexibility in producing small batch custom sizes – they manufactured M3.5 Brass Lock Nuts with specialized thin profiles for our latest product line with no minimum order quantity constraints, supporting our R&D initiatives. The material test certificates provided with each shipment give us complete traceability, which is essential for our ISO 17025 laboratory accreditation. Their willingness to accommodate our specific packaging requirements, including ESD-safe bags for electronic assembly areas, shows genuine commitment to customer satisfaction beyond just selling products. During a critical supply shortage last year, they expedited a rush order at standard pricing, preventing a costly production stoppage. The technical competence, responsive service, and consistent quality make them our preferred supplier for all Brass fastening components.”

GLOSSARY OF TECHNICAL TERMS

ACROSS FLATS (AF): The width dimension measured between parallel sides of a hexagonal nut, also called wrench size, determining the socket or wrench required for installation.

ALL-METAL LOCK NUT: A self-locking nut design utilizing deformed threads, spring elements, or mechanical interference without non-metallic inserts, suitable for high-temperature applications exceeding nylon service limits.

ASME B18.2.2: American Society of Mechanical Engineers standard specifying dimensions for square and hexagon nuts in unified inch thread sizes.

BRASS ALLOY: A family of Copper-based alloys primarily containing Zinc as the principal alloying element, offering excellent machinability, corrosion resistance, and attractive golden appearance.

BRITISH STANDARD WHITWORTH (BSW): Historic British thread standard featuring 55-degree thread angle, largely replaced by ISO metric and unified threads but still encountered in older equipment.

CERTIFICATE OF CONFORMANCE (CoC): Documentation certifying manufactured products comply with specified requirements including dimensional standards, material grades, and functional performance.

CHAMFER: Beveled edge at nut entry and exit ends facilitating thread engagement and preventing sharp edges that could damage mating threads or cause handling injuries.

CHROMATE CONVERSION COATING: Chemical surface treatment forming thin protective oxide layer on metal surfaces, providing corrosion resistance while maintaining electrical conductivity.

CZ121 (CW614N): European designation for free-cutting Brass containing approximately 58% Copper, 3% Lead, balance Zinc, widely used for high-speed machined components.

DEFORMED THREAD LOCK NUT: Self-locking nut design where thread profile is deliberately distorted in localized sections creating mechanical interference preventing loosening.

DIN STANDARDS: German Institute for Standardization (Deutsches Institut für Normung) technical specifications widely adopted internationally, particularly for fasteners and mechanical components.

ELECTROPLATING: Process depositing metallic coating on component surface through electrochemical means, commonly nickel, zinc, tin, or chrome providing enhanced corrosion resistance.

ELONGATION: Measure of material ductility expressed as percentage increase in length before fracture during tensile testing, indicating formability and impact resistance.

FLANGE NUT: Nut design incorporating integral washer-like flange distributing clamping load over larger area and potentially featuring serrations for enhanced locking.

FREE-CUTTING BRASS: Brass alloy containing lead additions (2.5-3.5%) enhancing machinability by facilitating chip breaking and reducing cutting tool wear during high-speed operations.

GALVANIC CORROSION: Accelerated corrosion occurring when dissimilar metals contact in presence of electrolyte, with more anodic metal experiencing preferential material loss.

HEXAGON (HEX): Six-sided geometric shape commonly used for nut external configuration, providing adequate wrench engagement surfaces while minimizing material and weight.

ISO 965: International standard specifying metric screw thread tolerances including pitch diameter, major diameter, and minor diameter allowances.

JAMMING ACTION: Locking mechanism where nut thread interference or secondary nut creates frictional resistance preventing loosening under vibration or dynamic loading.

LEAD-FREE BRASS: Brass alloy formulations limiting lead content below regulatory thresholds (typically <0.25%) for potable water contact applications, often utilizing bismuth, silicon, or other lead substitutes.