High Quality Aluminium Pressed Parts Aluminum Sheet Metal Components

Aluminium Pressed Components | Aluminium Sheet Metal Pressed Parts

Price: $ 6.80/kilogram

We are one of the leading manufacturers and exporters of Aluminium Pressed Components, Aluminum Sheet metal components, Aluminum pressing work, and Aluminium Sheet Metal Pressed Parts from India. We have been supplying precision-engineered sheet metal components to the world market for many decades. Our extensive manufacturing experience, in-house tooling capabilities, and commitment to quality have made us a trusted partner for global OEMs across automotive, electrical, telecom, HVAC, and appliance sectors. With a strong export footprint and deep understanding of international standards, we deliver components that consistently meet tight dimensional tolerances, aesthetic finish requirements, and performance expectations.

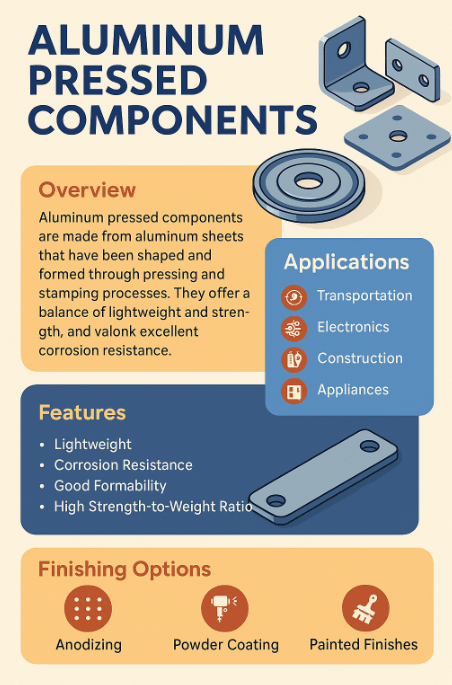

Overview

Aluminium sheet metal pressed components are manufactured using cold forming techniques where Aluminium sheets are blanked, punched, bent, drawn, or embossed into complex shapes. These parts are known for being lightweight, corrosion-resistant, conductive, and easy to assemble or join. We produce a wide range of Aluminium pressed parts from thicknesses of 0.4 mm to 4 mm using progressive dies, compound dies, and deep draw tooling.

Material Grades and Specifications

We work with a variety of Aluminium grades conforming to global specifications:

| Grade | Standards (ASTM/IS/BS) | Characteristics | Typical Applications |

|---|---|---|---|

| AA 1100 | ASTM B209 | Soft, good formability, corrosion resistant | Decorative, electronics |

| AA 3003 | ASTM B209 | Moderate strength, excellent corrosion | HVAC, enclosures |

| AA 5052 | ASTM B209, IS 737 | High strength, good weldability | Automotive, marine |

| AA 6061 | ASTM B221, DIN 1725 | Heat treatable, structural use | Telecom, frames, brackets |

| AA 8011 | IS 737 | Non-heat treatable, good drawability | Appliance panels, caps, consumer goods |

Mechanical Properties of AA 5052-H32

| Property | Typical Value |

| Tensile Strength | 215–265 MPa |

| Yield Strength | 180 MPa |

| Elongation | 7–10% |

| Density | 2.68 g/cm³ |

| Hardness | 65–75 HRB |

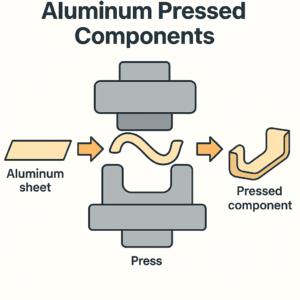

Manufacturing Process

Our Aluminium pressed parts are manufactured using:

- Sheet metal blanking and punching

- Piercing, notching, and lancing

- Press bending, flanging, hemming

- Deep drawing for cup- or can-like shapes

- Embossing and forming

Machinery Used

- Hydraulic Presses (20T to 250T)

- Pneumatic and Mechanical Power Presses

- CNC Turret Punch Machines

- CNC Press Brakes

- Progressive Die Setups

- Toolroom for in-house die and jig fabrication

- CMM and Profile Projectors for inspection

Finish Options

- Natural Aluminium Finish

- Powder Coated / Anodized / Painted

- Deburred and Buffed for assembly-readiness

- Protective film lamination (on request)

Industries Using Aluminium Pressed Parts

Our Aluminium pressed components are widely used in:

- Automotive and Transportation

- Electrical Enclosures and Panels

- HVAC Systems (louvers, housings)

- Telecom Equipment and Antenna Structures

- Consumer Electronics and Appliance Bodies

- Lighting Fixtures and Solar Assemblies

Tolerances and Dimensional Capability

| Parameter | Tolerance |

| Linear Dimension | ±0.1 mm to ±0.3 mm |

| Flatness | ±0.15 mm per 100 mm |

| Hole Positional Accuracy | ±0.2 mm |

| Surface Finish (Ra) | As low as 1.6 μm |

Typical Size Range of Parts Produced

| Operation | Size Range |

| Blanking | 20 mm to 400 mm |

| Bending | Upto 1000 mm length (1.2 mm thick) |

| Deep Drawing | Depth up to 80 mm |

| Thickness Range | 0.4 mm to 4 mm |

Typical Parts Produced

- Electrical and junction box covers

- Auto body reinforcement brackets

- Louvers and filter frames

- Appliance facia panels

- Battery connectors and casing parts

- Chassis components for telecom and solar

Turnaround Time

Our typical production lead time is 4–6 weeks from tool finalization or drawing approval. For existing tools or repeat parts, we can offer faster dispatch in 2–3 weeks. Samples are delivered within 10–15 working days depending on complexity.

Why Choose Us

Our success in Aluminium pressed components is rooted in:

- Over 30 years of metal forming expertise

- ISO-compliant processes and in-house toolroom

- Low MOQ options for development parts

- Flexible manufacturing suited for both batch and high-volume production

- Custom packaging, barcoding, and labeling

- Global supply chain support and compliance documentation

Frequently Asked Questions (FAQs)

- Can you supply press parts with surface finish?

- Yes, including anodizing, powder coating, and protective film.

- What tolerances can you maintain on blanked parts?

- Up to ±0.1 mm depending on part geometry.

- Do you offer tool design and development?

- Yes, we have an in-house toolroom for dies and fixtures.

- Can you handle progressive die operations?

- Absolutely, we have mechanical presses set up for progressive tools.

- What is your minimum order quantity?

- As low as 500 pcs depending on size and complexity.

- Do you export Aluminium pressed parts?

- Yes, we export to USA, UK, Germany, Gulf, and Southeast Asia.

- Can you develop parts from a physical sample?

- Yes, reverse engineering and drawing creation services are available.

- Do you test parts dimensionally?

- Yes, using CMM, height gauges, and profile projectors.

- Can you pack parts in custom trays or foam?

- Yes, we offer customized export packaging and kitting.

- What drawing formats do you accept?

- PDF, DXF, DWG, STEP, IGES, SolidWorks files.

Customer Testimonial

“We’ve worked with this team on multiple Aluminium sheet metal assemblies. They’re proactive, detail-oriented, and deliver exactly as promised. The consistency of dimensions and finish quality is excellent—even on high-volume orders. Great support for export compliance and packaging too.” — Adam W., California, USA

Glossary of Terms

- Blanking: Cutting the outline of a part from a sheet

- Piercing: Creating holes or cutouts

- Flanging: Bending the edge of the part to a specific angle

- Progressive Die: A tool that performs multiple forming operations in sequence

- Deep Drawing: Forming a flat sheet into a deep, hollow shape without rupture

Packaging and Shipping

Parts are cleaned, deburred, and packed in polybags, bubble wrap, or foam trays as required. Export cartons are barcode-labeled with customer details, part number, and batch information. Palletization with shrink wrap or wooden crates is used for sea shipments. Air freight and courier shipping available for urgent orders.

Related parts made by us-

Aluminium electrical panel components

HVAC Aluminium pressed louvers

Automotive Aluminium sheet metal parts

Aluminium junction box cover

Aluminium sheet metal components

Aluminium press parts manufacturer

Precision Aluminium stamped parts

Sheet metal Aluminium fabrications

Custom Aluminium pressing services

Aluminium stamping parts supplier

Aluminium pressed parts exporter India

CNC Aluminium sheet metal components

Call to Action

Looking for high-precision Aluminium Pressed Components? Email or WhatsApp us for a quick reply.