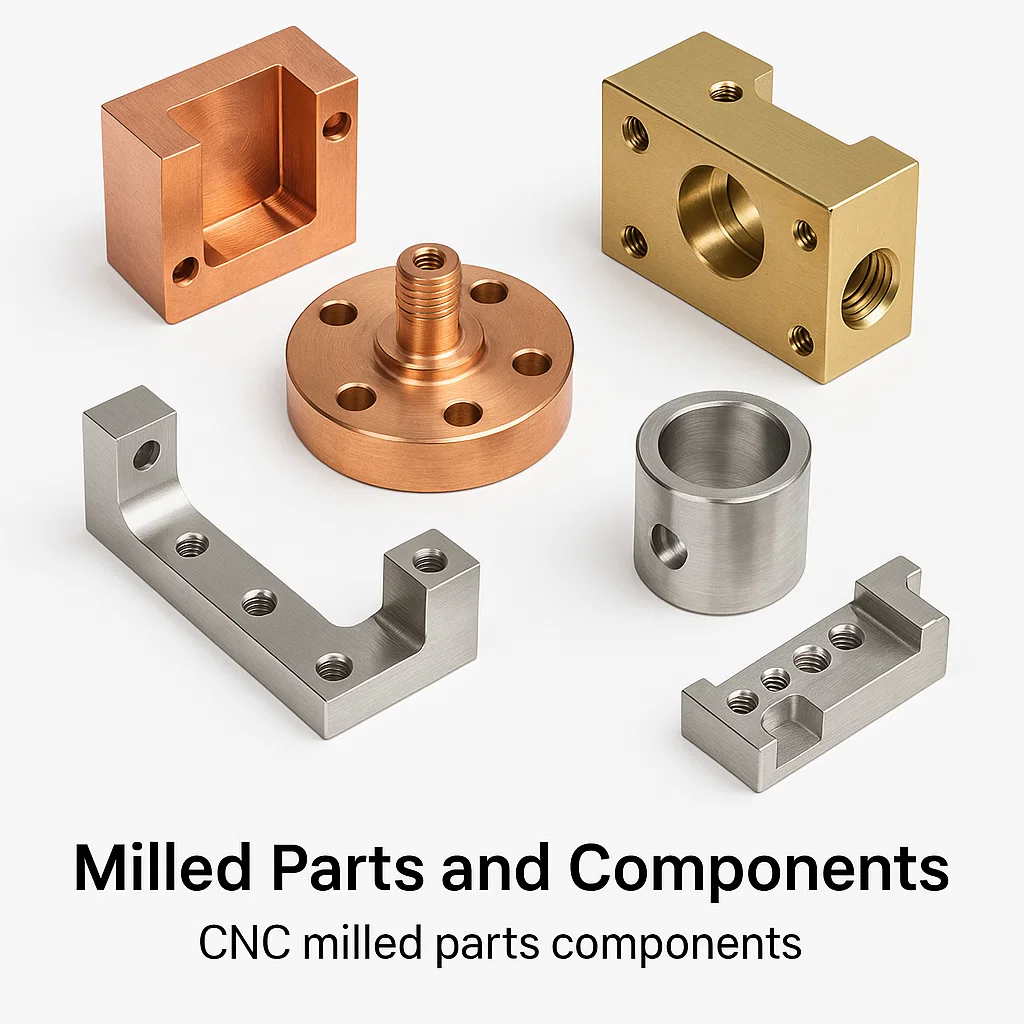

CNC Milled Parts, Milled Parts and Components – Precision Manufacturing Solutions

Overview – Precision CNC Milling Manufacturing

We are one of the leading manufacturers and exporters of CNC milled parts, precision milled components, and custom machined parts from India. We have been supplying high-quality milled parts and components to the world market for many decades. Our state-of-the-art CNC milling facilities utilize advanced computer numerical control technology to produce precision milled parts with exceptional accuracy and repeatability. Our comprehensive range includes Brass milled components, Stainless Steel milled parts, Copper CNC milled parts, Aluminum milled components, and specialized precision CNC milling work across various industrial applications. With over three decades of manufacturing excellence, we deliver custom CNC machined parts that meet stringent international quality standards including ASTM, DIN, JIS, BS, and IS specifications. Our precision milling capabilities encompass complex geometries, tight tolerances, and superior surface finishes for automotive, aerospace, electronics, medical devices, and industrial machinery sectors. We combine traditional craftsmanship with modern CNC technology to ensure every milled component meets exact customer specifications while maintaining cost-effectiveness and reliable delivery schedules. We also specialize in Copper CNC parts, Swiss machined parts, Stainless Steel CNC machined components, precision machining of Stainless Steel, Brass, Aluminum and Copper.

Brass CNC Milled Parts and Brass Milled Components

Our Brass CNC milled parts are manufactured using premium quality Brass alloys including CuZn37 (CW508L), CuZn39Pb3 (CW614N), and CuZn40 (CW509L) conforming to international standards. Brass milled components offer excellent machinability, corrosion resistance, and aesthetic appeal making them ideal for decorative hardware, electrical components, plumbing fittings, and precision instruments. Our CNC milling centers produce complex Brass parts with tolerances as tight as ±0.05mm, featuring superior surface finishes ranging from Ra 0.8 to Ra 3.2 micrometers. Common applications include valve bodies, connector housings, decorative architectural elements, marine hardware, and precision measurement instruments where Brass’s antimicrobial properties and electrical conductivity are essential.

Stainless Steel Milled Parts and Components

Stainless Steel milled parts represent our core competency in precision manufacturing, utilizing grades including 304L (1.4307), 316L (1.4404), 321 (1.4541), 410 (1.4006), and duplex 2205 (1.4462) per ASTM A240, DIN EN 10088, and JIS G4305 standards. Our Stainless Steel CNC milling capabilities produce components for pharmaceutical equipment, food processing machinery, chemical processing plants, and marine applications where corrosion resistance and hygiene are paramount. Advanced multi-axis CNC milling centers enable complex geometries including undercuts, internal cavities, and intricate surface textures while maintaining dimensional accuracy within ±0.02mm. Typical products include pump housings, valve components, surgical instruments, and pressure vessel parts with mirror-polished or electropolished finishes.

Copper CNC Milled Parts and Components

Copper CNC milled parts leverage Copper’s exceptional thermal and electrical conductivity properties, manufactured from C101 (99.9% pure), C110 (ETP), and C145 (tellurium Copper) grades conforming to ASTM B152, DIN EN 1172, and JIS H3100 specifications. Our Copper milled components are essential for electrical switchgear, heat exchangers, electromagnetic shielding, and high-frequency electronic applications. Precision CNC milling of Copper requires specialized tooling and cutting parameters to achieve optimal surface finish and dimensional stability. We produce Copper parts including bus bars, heat sinks, electrical contacts, and waveguide components with excellent surface conductivity and minimal work hardening, maintaining tolerances of ±0.03mm across complex geometries.

Aluminum Milled Components and Precision Parts

Aluminum milled components showcase our expertise in lightweight precision manufacturing using alloys including 6061-T6, 7075-T6, 2024-T3, and 5083-H111 per ASTM B211, EN AW standards, and JIS H4000 specifications. Aluminum CNC milling delivers exceptional strength-to-weight ratios essential for aerospace, automotive, and electronics industries. Our advanced CNC machining centers produce complex Aluminum parts with intricate internal passages, thin-wall sections, and precision threaded features while maintaining structural integrity. Typical applications include aircraft components, automotive parts, electronic enclosures, and optical instrument housings with anodized, hard coat anodized, or chemical conversion coatings for enhanced durability and corrosion protection.

Precision CNC Milling Work and Custom Manufacturing

Precision CNC milling work encompasses our comprehensive machining capabilities utilizing 3-axis, 4-axis, and 5-axis CNC milling centers from leading manufacturers including DMG Mori, Haas, and Mazak. Our custom CNC milling services handle complex geometries, multi-feature parts, and high-precision components requiring tolerances down to ±0.01mm. Advanced CAD/CAM software integration ensures optimal tool paths, reduced cycle times, and consistent quality across production runs. We specialize in prototype development, low to medium volume production, and complex assemblies requiring secondary operations including drilling, tapping, counterboring, and surface treatments for complete turnkey solutions.

Material Grades and International Standards

| Material | International Grades | USA Standards | European Standards | Japanese Standards | Chinese Standards |

|---|---|---|---|---|---|

| Brass | CuZn37, CuZn39Pb3, CuZn40 | ASTM B16, UNS C36000 | EN CW508L, CW614N | JIS H3250 C3604 | GB/T 4423 H62, H65 |

| Stainless Steel | 304L, 316L, 321, 410 | ASTM A240, AISI 304 | EN 1.4307, 1.4404 | JIS G4305 SUS304L | GB/T 3280 0Cr18Ni9 |

| Copper | C101, C110, C145 | ASTM B152, UNS C11000 | EN CW004A, CW008A | JIS H3100 C1020 | GB/T 2040 T2, T3 |

| Aluminum | 6061-T6, 7075-T6, 2024 | ASTM B211, AA 6061 | EN AW-6061, AW-7075 | JIS H4000 A6061 | GB/T 3190 6061, 7075 |

Manufacturing Processes and Advanced CNC Machinery

Our precision CNC milling processes utilize computer-controlled machining centers equipped with high-speed spindles, automatic tool changers, and advanced workholding systems. The manufacturing workflow begins with detailed CAD analysis, followed by CAM programming using industry-standard software including Mastercam, PowerMill, and Fusion 360. Our CNC milling operations include face milling, end milling, slot milling, profile milling, and complex 3D contouring with simultaneous multi-axis interpolation.

Advanced CNC machinery in our facility includes vertical machining centers with spindle speeds up to 15,000 RPM, horizontal machining centers for complex prismatic parts, and 5-axis simultaneous milling centers for aerospace components. Workpiece positioning accuracy of ±0.002mm is achieved through precision ball screw drives, linear encoders, and temperature-controlled environments. Coolant flood systems, through-spindle coolant delivery, and high-pressure coolant options ensure optimal cutting conditions and superior surface finishes.

| Machine Type | Spindle Speed (RPM) | Work Envelope (mm) | Position Accuracy | Surface Finish (Ra) |

|---|---|---|---|---|

| 3-Axis Vertical Machining Center | 8,000 – 12,000 | 1000 x 500 x 400 | ±0.005mm | 0.8 – 3.2 μm |

| 4-Axis Horizontal Machining Center | 6,000 – 10,000 | 800 x 800 x 600 | ±0.003mm | 0.4 – 1.6 μm |

| 5-Axis Simultaneous Milling | 15,000 – 20,000 | 600 x 600 x 500 | ±0.002mm | 0.2 – 0.8 μm |

Typical Parts Produced and Applications

Our CNC milled parts manufacturing capabilities encompass a diverse range of components including valve bodies, pump housings, gear cases, electronic enclosures, heat sinks, connector blocks, and precision instrument housings. Custom milled components are produced for specific applications such as automotive transmission parts, aerospace structural components, medical device housings, and industrial automation equipment.

Typical Component Dimensions and Specifications

Length (L)Height (H)Width (W)

| Dimension | Minimum (mm) | Maximum (mm) | Tolerance (mm) | Surface Finish (Ra μm) |

|---|---|---|---|---|

| Length (L) | 5 | 1200 | ±0.02 | 0.4 – 3.2 |

| Width (W) | 3 | 800 | ±0.03 | 0.8 – 6.3 |

| Height (H) | 2 | 600 | ±0.05 | 1.6 – 12.5 |

Surface Finishes and Quality Standards

Surface finish specifications for our CNC milled parts range from mirror-polished Ra 0.1 micrometers to standard machined Ra 6.3 micrometers depending on application requirements. Precision milling surface treatments include mechanical polishing, electropolishing, passivation, anodizing, plating, and specialized coatings. Quality control procedures involve coordinate measuring machines (CMM), surface roughness testers, hardness testing, and material certification to ensure compliance with customer specifications and international standards.

| Surface Finish | Ra Value (μm) | Application | Additional Treatment |

|---|---|---|---|

| Mirror Polish | 0.1 – 0.4 | Optical, Medical | Electropolishing |

| Fine Machined | 0.8 – 1.6 | Precision Instruments | Passivation |

| Standard Machined | 3.2 – 6.3 | General Engineering | Deburring |

| Textured | 12.5 – 25 | Grip Surfaces | Bead Blasting |

Industries and Applications

CNC milled parts industries served include aerospace where precision Aluminum and Stainless Steel components meet stringent AS9100 requirements, automotive sector requiring high-volume production of transmission housings and engine components, medical device manufacturing demanding biocompatible materials and FDA compliance, electronics industry needing EMI shielding and thermal management solutions, and oil and gas sector requiring corrosion-resistant Stainless Steel and special alloy components.

Additional sectors include defense and military applications requiring specialized materials and security clearances, renewable energy equipment including wind turbine components and solar tracking systems, telecommunications infrastructure demanding precision RF components and antenna housings, and marine industry requiring Brass and Bronze components resistant to saltwater corrosion.

🏭 CNC Milling Process Flow

Design Analysis → CAM Programming → Tool Selection → Workholding Setup → CNC Machining → Quality Inspection → Surface Treatment → Final Packaging

Delivering precision milled parts with 99.8% quality compliance rate

Precision Tolerances and Performance Metrics

Precision milling tolerances achieved in our facility range from standard ±0.1mm for general engineering applications to ultra-precision ±0.01mm for critical aerospace and medical components. Performance metrics include dimensional accuracy verified through statistical process control, surface finish consistency monitored via continuous sampling, and delivery performance exceeding 95% on-time completion rates.

| Tolerance Grade | Linear Dimensions | Angular Dimensions | Surface Finish Ra | Applications |

|---|---|---|---|---|

| Ultra Precision | ±0.01mm | ±0.1° | 0.1 – 0.4 μm | Aerospace, Medical |

| High Precision | ±0.02mm | ±0.2° | 0.4 – 0.8 μm | Electronics, Optics |

| Precision | ±0.05mm | ±0.5° | 0.8 – 1.6 μm | Automotive, Industrial |

| Standard | ±0.1mm | ±1.0° | 3.2 – 6.3 μm | General Engineering |

Material Properties and Technical Specifications

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Electrical Resistivity (nΩ·m) | Machinability Rating |

|---|---|---|---|---|---|

| Brass CuZn37 | 8.5 | 320-450 | 120 | 62 | 80% |

| Stainless Steel 316L | 8.0 | 485-620 | 16 | 740 | 45% |

| Copper C110 | 8.9 | 220-290 | 391 | 17 | 20% |

| Aluminum 6061-T6 | 2.7 | 290-310 | 167 | 28 | 90% |

Turnaround Time and Production Schedule

Standard turnaround time for CNC milled parts is 4-6 weeks from order confirmation, including design review, programming, machining, quality inspection, and finishing operations. Express production services are available for urgent requirements with 2-3 week delivery for standard components. Complex multi-feature parts requiring extensive secondary operations may require 6-8 weeks depending on specifications and quantity requirements.

Production planning incorporates lean manufacturing principles with just-in-time delivery options, progress tracking through ERP systems, and regular customer updates throughout the manufacturing cycle. Batch production efficiency enables competitive pricing for medium to high volume orders while maintaining flexibility for prototype and low-volume custom requirements.

Customer Testimonial

Robert Thompson, Procurement Manager, Advanced Manufacturing Solutions Inc., California, USA:

“Working with this Indian manufacturer for our precision CNC milled parts has been exceptional. Their attention to detail, consistent quality, and ability to meet our tight aerospace tolerances has made them our preferred supplier for over 5 years. The communication throughout the project lifecycle is outstanding, and they consistently deliver on time. Their expertise in working with various materials and complex geometries has helped us reduce costs while improving part quality. I highly recommend their CNC milling services to any company requiring precision components.”

Comprehensive Q&A Session – CNC Milled Parts

Q1: What is the minimum tolerance achievable for CNC milled parts?

A: Our precision CNC milling capabilities can achieve tolerances as tight as ±0.01mm for critical dimensions on aerospace and medical components, with standard tolerances of ±0.05mm for general engineering applications.

Q2: Which materials offer the best machinability for complex CNC milled components?

A: Aluminum alloys like 6061-T6 offer excellent machinability (90% rating), followed by Brass alloys (80% rating). Stainless Steel requires specialized tooling but produces superior corrosion resistance for demanding applications.

Q3: What surface finishes are available for precision milled parts?

A: We provide surface finishes ranging from Ra 0.1μm mirror polish for optical applications to Ra 25μm textured surfaces for grip applications, including electropolishing, anodizing, and specialized coatings.

Q4: Can you handle both prototype and production quantities for CNC milled parts?

A: Yes, our flexible manufacturing setup accommodates single prototype parts to production runs of 10,000+ pieces with consistent quality and competitive pricing structures for different volume requirements.

Q5: What quality certifications do you maintain for CNC milling operations?

A: Our facility maintains ISO 9001:2015 certification with aerospace AS9100 and medical device ISO 13485 compliance, ensuring traceability and quality control throughout the manufacturing process.

Q6: How do you ensure dimensional accuracy for complex geometries?

A: We utilize coordinate measuring machines (CMM), laser measuring systems, and statistical process control with real-time monitoring to maintain dimensional accuracy and provide detailed inspection reports.

Q7: What is the typical lead time for custom CNC milled parts?

A: Standard lead time is 4-6 weeks including design review, programming, machining, and quality inspection. Express services available for 2-3 week delivery on standard components.

Q8: Do you provide material certificates and traceability documentation?

A: Complete material certification including mill test certificates, chemical composition analysis, mechanical properties, and full traceability documentation is provided with every shipment.

Q9: What secondary operations can be performed on CNC milled parts?

A: Secondary operations include precision drilling, tapping, counterboring, deburring, surface treatments, assembly, and custom packaging with customer logos and labeling requirements.

Q10: How do you handle design modifications during the manufacturing process?

A: Our engineering team provides design review and optimization suggestions before production begins. Minor modifications can be accommodated during manufacturing with proper documentation and customer approval.

Q11: What inspection equipment is used for quality control?

A: Quality inspection utilizes coordinate measuring machines, optical comparators, surface roughness testers, hardness testers, and specialized gauges calibrated to international standards.

Q12: Can you provide cost-effective solutions for high-volume CNC milling projects?

A: Volume pricing structures, dedicated production lines, and lean manufacturing techniques enable competitive pricing for high-volume orders while maintaining quality standards and delivery schedules.

Why Choose Our CNC Milled Parts Over Competitors

Global Experience and Expertise: With over three decades of manufacturing excellence, our team brings unmatched experience in precision CNC milling across diverse industries and applications. Our global exposure includes successful partnerships with companies in USA, Europe, Australia, and Asia-Pacific regions.

Faster Turnaround Times: Our streamlined production processes, advanced planning systems, and dedicated project management ensure faster delivery compared to industry standards. Express manufacturing options available for urgent requirements without compromising quality.

Superior Customer Support and Communication: Dedicated project managers provide regular updates, technical support, and responsive communication throughout the manufacturing cycle. English-speaking technical team ensures clear communication and understanding of requirements.

Customization Flexibility: Our engineering team specializes in custom solutions, design optimization, and value engineering to meet specific customer requirements while reducing costs and improving functionality.

Customized Packaging and Branding: Complete packaging solutions including custom labeling, customer logos, specialized protective packaging, and documentation tailored to customer requirements and international shipping standards.

International Standards Compliance

Our CNC milled parts manufacturing strictly adheres to international quality and safety standards including IS (Indian Standards) for local compliance, BS (British Standards) for European markets, ASTM (American Society for Testing and Materials) for North American applications, DIN (German Industrial Standards) for precision engineering, and JIS (Japanese Industrial Standards) for Asian markets. Additional certifications include ISO 9001:2015 for quality management, AS9100 for aerospace applications, and ISO 13485 for medical device manufacturing.

Packaging and International Shipping

Specialized packaging solutions protect CNC milled parts during international transportation using anti-corrosion VCI papers, custom foam inserts, wooden crates for heavy components, and moisture barrier bags for sensitive materials. Shipping documentation includes commercial invoices, packing lists, material certificates, inspection reports, and certificates of origin for customs clearance. Partnership with international freight forwarders ensures reliable delivery to global destinations with full shipment tracking and insurance coverage.

Size and Dimensional Capabilities Chart

| Component Category | Minimum Size (mm) | Maximum Size (mm) | Wall Thickness (mm) | Hole Diameter (mm) | Thread Size |

|---|---|---|---|---|---|

| Micro Components | 2 x 2 x 1 | 50 x 50 x 25 | 0.5 | 0.3 | M1.0 |

| Small Precision Parts | 10 x 10 x 5 | 200 x 200 x 100 | 1.0 | 1.0 | M2.0 |

| Medium Components | 50 x 50 x 25 | 600 x 400 x 300 | 2.0 | 3.0 | M6.0 |

| Large Assemblies | 200 x 200 x 100 | 1200 x 800 x 600 | 5.0 | 6.0 | M20 |

Advanced CNC Milling Technologies and Equipment

State-of-the-art CNC milling equipment includes high-speed machining centers with spindle speeds exceeding 20,000 RPM for Aluminum aerospace components, heavy-duty horizontal machining centers for large Stainless Steel parts, and specialized micro-milling machines for miniature precision components. Advanced tooling systems feature carbide end mills, ceramic cutting tools, and diamond-coated tools for superior surface finishes and extended tool life.

Computer-aided manufacturing (CAM) software integration enables optimized tool paths, reduced cycle times, and consistent repeatability across production batches. Real-time monitoring systems track cutting forces, spindle vibration, and tool wear to prevent quality issues and ensure optimal machining conditions for each material type.

Quality Assurance and Testing Procedures

Comprehensive quality control procedures begin with incoming material inspection using spectrometers for chemical composition verification, hardness testing, and dimensional verification of raw materials. In-process monitoring includes statistical process control with automated data collection, real-time dimensional monitoring, and surface finish verification at critical manufacturing stages.

Final inspection protocols utilize coordinate measuring machines with probe accuracy of ±0.001mm, optical measuring systems for complex geometries, and specialized testing for material properties including tensile strength, corrosion resistance, and fatigue life where applicable. Complete inspection reports with photographic documentation accompany every shipment.

Competitive Advantages and Unique Selling Propositions

Manufacturing flexibility allows production schedule adjustments to meet customer urgency requirements while maintaining quality standards. Engineering support services include design for manufacturability (DFM) analysis, cost optimization recommendations, and alternative material suggestions to improve performance and reduce costs.

Global supply chain management ensures consistent raw material quality through partnerships with certified suppliers worldwide, while local sourcing options provide cost advantages for standard materials. Technology investment in latest CNC equipment, measurement systems, and software ensures competitive advantages in precision, efficiency, and capability.

Specialized Finishing Options and Surface Treatments

| Finish Type | Materials Applicable | Typical Ra Value | Corrosion Resistance | Applications |

|---|---|---|---|---|

| Electropolishing | Stainless Steel | 0.1 – 0.4 μm | Excellent | Pharmaceutical, Food |

| Hard Anodizing | Aluminum | 0.8 – 1.6 μm | Very Good | Aerospace, Military |

| Nickel Plating | Brass, Copper | 0.4 – 0.8 μm | Good | Electronics, Decorative |

| Passivation | Stainless Steel | As Machined | Enhanced | Medical, Chemical |

Environmental Compliance and Sustainability

Environmental management systems ensure compliance with international environmental standards including ISO 14001 certification. Sustainable manufacturing practices include recycling of metal chips and coolants, energy-efficient CNC equipment operation, and waste minimization through optimized programming and material utilization. Water treatment systems manage coolant disposal while meeting local environmental regulations.

Related Parts-

Related manufacturing terms: CNC machining services, precision milling work, custom machined parts, computer numerical control milling, multi-axis machining, prototype machining, production milling, contract manufacturing, precision engineering, mechanical components manufacturing, industrial machining services, custom metal fabrication, precision turned parts, CNC turning and milling, automated machining, high precision manufacturing, metal cutting services, aerospace machining, automotive parts manufacturing, medical device components, marine hardware manufacturing, defense component manufacturing, optical component machining, telecommunications parts manufacturing, renewable energy components.

Glossary of Technical Terms

| Term | Definition | Related Keywords |

|---|---|---|

| CNC Milling | Computer Numerical Control machining process using rotating cutting tools to remove material | Precision milling, automated machining |

| Tolerance | Allowable deviation from specified dimensions | Dimensional accuracy, precision manufacturing |

| Surface Finish (Ra) | Arithmetic average roughness measured in micrometers | Surface quality, finish specification |

| Machinability | Relative ease of machining different materials | Material properties, cutting parameters |

| CAM Programming | Computer-Aided Manufacturing software for CNC programming | Tool path optimization, machining strategy |

| Workholding | Methods and devices for securing workpieces during machining | Fixturing, clamping systems |

Technical Specifications and Capabilities Summary

Maximum component dimensions: 1200mm x 800mm x 600mm with positioning accuracy of ±0.002mm across the entire work envelope. Material thickness capabilities range from 0.5mm thin sections to 200mm thick blocks with specialized workholding for challenging geometries. Production capacity includes 50+ CNC machining centers operating in multiple shifts to meet demanding delivery schedules while maintaining consistent quality standards.

Advanced measurement capabilities include coordinate measuring machines with touch probe systems, laser interferometry for ultra-precision measurement, optical measuring systems for complex profiles, and portable measurement arms for large component verification. Material handling systems accommodate components from miniature precision parts to large industrial assemblies with appropriate lifting and positioning equipment.

📊 Manufacturing Excellence Metrics

Quality Performance: 99.8% First Pass Yield | Delivery Performance: 96% On-Time Delivery | Customer Satisfaction: 98.5% Rating

Precision Achievement: ±0.01mm Tolerance Capability | Surface Finish: Ra 0.1μm Mirror Polish | Global Reach: 45+ Countries Served

Industry Applications and Sector Expertise

Aerospace industry applications include structural components, landing gear parts, engine accessories, and avionics housings requiring AS9100 certification and stringent material traceability. Medical device manufacturing encompasses surgical instruments, implant components, diagnostic equipment housings, and pharmaceutical processing equipment with biocompatible materials and FDA compliance.

Automotive sector components include transmission housings, engine blocks, brake system parts, and electronic control unit housings with high-volume production capabilities and automotive quality standards. Electronics industry solutions feature EMI shielding enclosures, heat sinks, connector housings, and precision electronic component mounting hardware with tight tolerance requirements.

Oil and gas industry applications encompass valve components, pump housings, pressure vessel parts, and pipeline fittings manufactured from corrosion-resistant Stainless Steel and special alloys meeting NACE and API standards. Marine industry components include propeller hubs, deck hardware, navigation equipment housings, and seawater-resistant fittings utilizing Brass, Bronze, and marine-grade Stainless Steel materials.

Cost Optimization and Value Engineering Services

Design for manufacturability analysis identifies opportunities to reduce manufacturing costs while maintaining functionality and quality requirements. Material optimization studies evaluate alternative materials offering similar performance characteristics at reduced costs or improved properties for specific applications.

Production volume analysis determines optimal manufacturing approaches for different quantity requirements, including investment casting for high volumes, CNC milling for medium volumes, and rapid prototyping for development stages. Total cost of ownership evaluation considers manufacturing costs, logistics, inventory requirements, and lifecycle maintenance to provide comprehensive cost solutions.

Global Logistics and Supply Chain Management

International shipping expertise includes comprehensive logistics management with freight forwarding partnerships, customs documentation preparation, and delivery tracking systems. Inventory management services offer consignment stocking, scheduled deliveries, and vendor-managed inventory programs to optimize customer cash flow and reduce carrying costs.

| Shipping Method | Typical Transit Time | Suitable for | Documentation Required |

|---|---|---|---|

| Air Freight | 3-7 days | Urgent, High Value | AWB, Commercial Invoice |

| Sea Freight | 15-45 days | Standard, Bulk Orders | B/L, Packing List |

| Express Courier | 2-5 days | Samples, Small Parts | Courier Documentation |

Technology Integration and Industry 4.0 Capabilities

Smart manufacturing integration includes IoT-enabled CNC machines with real-time monitoring, predictive maintenance systems, and automated quality control feedback loops. Digital twin technology enables virtual machining simulation, process optimization, and quality prediction before actual production begins.

Advanced data analytics track production efficiency, quality trends, and customer satisfaction metrics to continuously improve manufacturing processes and customer service levels. Automated reporting systems provide customers with real-time production status updates, quality data, and shipment tracking information through secure web portals.

Get Your Custom CNC Milled Parts Quote Today

Ready to experience precision manufacturing excellence?

📧 Email us your drawings and specifications for a detailed technical quote and manufacturing proposal – sales@a1metallics. com

📞 Call us directly at +91-22-43449300 for immediate technical consultation