Copper CNC Machined Parts CNC Turned Components of Copper

PRICE= $12/Kg

Based in Jamnagar India, we are leading manufacturers of high-precision copper CNC machined parts and components. With over 25 years of experience, we combine traditional craftsmanship with cutting-edge CNC technology to deliver superior quality components to global clients.

Manufacturing Processes

CNC Turning

- Precision diameter control

- Complex profiling

- Capacity up to 500mm diameter

- Surface finish up to Ra 0.4

CNC Milling

- 3-axis and 4-axis machining

- Complex geometries

- High-precision slots and pockets

- Tolerances up to ±0.01mm

Threading Operations

- Internal and external threading

- Metric and imperial standards

- Custom thread profiles

- Multi-start threads

Copper Material Types We Work With

We offer machining solutions in a wide range of copper grades, including:

| Material Grade | Description | Applications |

|---|---|---|

| C101 (Oxygen-Free Copper) | High electrical conductivity and excellent ductility. | Electrical and thermal systems. |

| C110 (Electrolytic Tough Pitch) | Exceptional balance of strength, conductivity, and corrosion resistance. | Switchgears, terminals, connectors. |

| C182 (Chromium Copper) | High strength and wear resistance. | Welding electrodes, industrial tools. |

| C172 (Beryllium Copper) | Excellent hardness and fatigue resistance. | Aerospace, connectors, springs. |

| C260 (Cartridge Brass) | High corrosion resistance with moderate strength. | Plumbing, marine hardware. |

| C655 (Silicon Bronze) | High strength and weldability. | Marine, architectural us |

Pure Copper Grades

- ETP Copper (C11000)

- DHP Copper (C12200)

- Oxygen-Free Copper (C10200)

- Fire-Refined Copper (C12500)

Copper Alloys

- Brass (Various grades)

- Bronze (Phosphor and Aluminum)

- Beryllium Copper

- Copper-Nickel Alloys

Typical Components

Copper Electrical Components

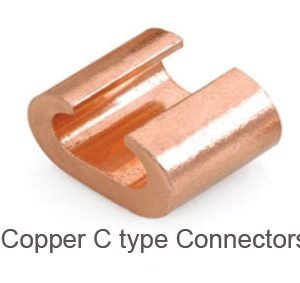

- Bus Bar Connectors

- Terminal Blocks

- Switch Components

- Heat Sink Elements

- Copper Connectors, Copper busbars

- Copper Transformer connectors, Copper alloy (Bronze) spade terminals

- Copper alloy-Bronze vise connectors,

- Copper alloy-Bronze Hotline clamps

Industrial Components

- Valve Components

- Pump Parts

- Heat Exchanger Parts

- Bearing Components

Precision Parts

- Custom Bushings

- Threaded Fittings

- Specialized Fasteners

- Mechanical Couplings

Core Industries

- Power Generation & Distribution

- Electrical Equipment Manufacturing

- Automotive & Transportation

- Marine & Offshore

Specialized Sectors

- Renewable Energy Systems

- Industrial Automation

- Defense & Aerospace

- Medical Equipment

Our own Copper casting foundry and Forging shop can also offer Copper forged parts and components- Copper Castings that can be CNC machined and turned/milled.

Quality Assurance

Our facility is ISO 9001:2015 certified, equipped with state-of-the-art CMM (Coordinate Measuring Machine) and advanced inspection equipment. We ensure:

- 100% inspection of critical dimensions

- Material certification and traceability

- First Article Inspection Reports (FAIR)

- Customer-specific quality documentation

Q1: What are Copper CNC Machined Parts?

A: Copper CNC machined parts are precision Copper Machined components made from Copper bars or Copper alloys using Computer Numerical Control (CNC) machining. This process involves using automated machine tools to cut, shape, and fabricate parts with high accuracy and consistency. Copper is chosen for its excellent electrical conductivity, thermal conductivity, and corrosion resistance, making it ideal for industries like electronics, automotive, and aerospace.

Q2: What are the advantages of using Copper for CNC machining?

A: Copper offers several advantages for CNC machining, including:

- High Electrical Conductivity: Perfect for electrical and electronic components.

- Thermal Conductivity: Ideal for heat exchangers and cooling systems.

- Corrosion Resistance: Suitable for harsh environments.

- Machinability: Copper is relatively easy to machine, allowing for intricate designs and tight tolerances.

- Aesthetic Appeal: Copper parts have a distinctive, attractive finish.

Q3: What industries commonly use Copper CNC machined parts and CNC Machined Components?

A: Copper CNC machined parts are widely used in industries such as:

- Electronics: For connectors, terminals, and circuit components.

- Automotive: For sensors, bushings, and electrical systems.

- Aerospace: For components requiring high thermal and electrical performance.

- Plumbing: For fittings, valves, and fixtures.

- Renewable Energy: For solar panels and wind turbine components.

Q4: What is the difference between CNC machining and CNC turning for Copper parts?

A: CNC machining is a broad term that includes various processes like milling, drilling, and cutting to create complex 3D shapes. CNC turning, on the other hand, is a specific process where the workpiece rotates while a cutting tool removes material to create cylindrical or round parts. Both methods are used for Copper parts, with turning being ideal for symmetrical components like shafts, pins, and connectors.

Q5: What tolerances can be achieved with Copper CNC machining?

A: Copper CNC machining can achieve tight tolerances, typically within ±0.001 inches (±0.025 mm) or better, depending on the part design and machining process. This precision ensures that the parts meet strict industry standards and perform reliably in their applications.

Q6: Can Copper CNC machined parts be customized?

A: Yes, Copper CNC machined parts can be fully customized to meet specific design requirements. Whether you need unique shapes, sizes, or surface finishes, CNC machining offers the flexibility to create tailored solutions for your application.

Q7: What surface finishes are available for Copper CNC parts?

A: Common surface finishes for Copper CNC parts include:

- Polished: For a smooth, reflective surface.

- Plated: To enhance corrosion resistance or add a decorative layer (e.g., nickel or gold plating).

- Anodized: For improved durability and color options.

- Bead Blasted: For a matte, non-reflective finish.

Q8: How do I ensure the quality of Copper CNC machined parts?

A: Quality can be ensured by:

- Working with a reputable manufacturer with experience in Copper machining.

- Providing detailed design specifications and tolerances.

- Requesting material certifications and quality control reports.

- Conducting inspections and testing (e.g., dimensional checks, conductivity tests).

Q9: What are the lead times for Copper CNC machined parts?

A: Lead times vary depending on the complexity of the part, order quantity, and manufacturer capacity. Typically, lead times range from a few days to several weeks. Discuss your timeline with your supplier to ensure timely delivery.

Q10: How do I choose the right supplier for Copper CNC machined parts CNC machined Copper Components?

A: When choosing a supplier, consider:

- Experience: Look for a supplier with expertise in Copper machining.

- Capabilities: Ensure they have the right equipment and technology.

- Quality Standards: Check for certifications like ISO 9001.

- Customer Reviews: Read testimonials or ask for references.

- Cost and Lead Time: Compare quotes and delivery schedules.

Q11: Are there any design tips for Copper CNC machined parts and Copper Components?

A: Yes, here are some tips:

- Avoid overly thin walls to prevent deformation.

- Design with standard tool sizes in mind to reduce costs.

- Specify tolerances only where necessary to save time and money.

- Consider the material’s softness and plan for proper handling during machining.

Q12: Can Copper CNC parts be combined with other materials?

A: Absolutely! Copper CNC parts , Copper Parts and Copper components machined Copper parts and machined Copper Components can be combined with other materials like brass, aluminum, or plastics to create hybrid components. This is common in applications requiring both electrical conductivity and structural strength.