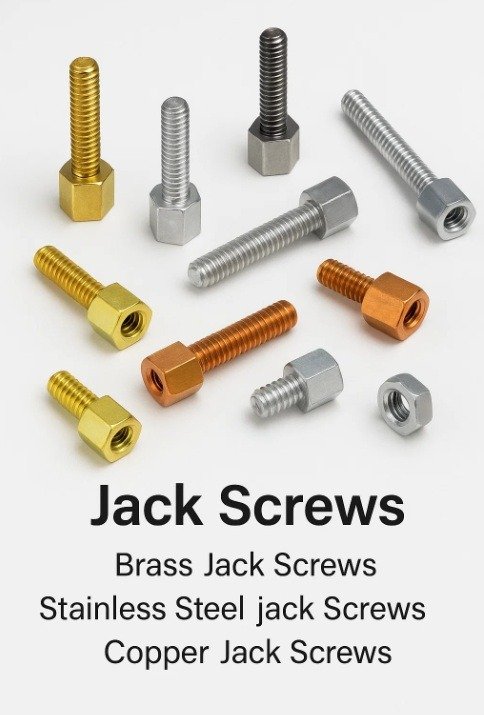

Electronic Jack Screws, Brass Jack Screws, Copper Jack Screws, Stainless Steel Jack Screws

Jack Screws are essential components in the electronics and computer hardware industries. They are most commonly used to fasten D-subminiature cable connectors securely to their corresponding ports. Additionally, Jack Screws play a vital role in multi-layer printed circuit boards (PCBs), where they help fasten components together while maintaining precise spacing for effective heat dissipation. Depending on the application, Jack Screws can support low, medium, or heavy load-bearing requirements, making them versatile fasteners across various electronic assemblies.

We are one of the leading manufacturers and exporters of Jack Screws from India. We have been supplying Electronic Jack Screws, Brass Jack Screws, Copper Jack Screws, and Stainless Steel Jack Screws to the world market for many decades. Our jack screws are engineered with precision, offering dependable fastening and unfastening solutions for electronic and mechanical assemblies. These screws are compatible with a wide range of applications including computer connectors, D-sub connectors, control panels, data communication ports, and aerospace interfaces. Available in metric threads (M2–M8) and UNC threads (4-40, 6-32, 8-32), our Jack Screws are manufactured using top-quality raw materials compliant with international standards such as ASTM, DIN, JIS, BS, and IS. We leverage CNC and VMC precision machines to achieve tight tolerances, consistent performance, and durable threading profiles.

Our production capabilities include custom design, low to high-volume flexibility, and support for specialized plating finishes such as nickel, tin, silver, and zinc. We also offer private labeling and customized packaging for OEMs and distributors. With a standard turnaround of 4–6 weeks and robust export packaging, we ensure timely delivery and product integrity during transit.

Electronic Jack Screws Electronic Jack Screws are primarily used in electronic devices for panel mounting and securing D-sub connectors. Made from non-magnetic, corrosion-resistant materials like Brass and Stainless Steel, these screws are available in both knurled and slotted variants. We manufacture Electronic Jack Screws with precision-rolled threads and optional captive washers or spacers. These jack screws are essential in communication equipment, control units, avionics, and high-reliability computing. Our electronic-grade jack screws comply with IPC and RoHS standards and come with options for customized screw lengths and spacers.

Brass Jack Screws Brass Jack Screws are favored for their excellent machinability, electrical conductivity, and aesthetic appeal. We offer Brass Jack Screws in grades like IS 319 Type I/II, BS 2874 CZ121, ASTM B16, and JIS C3604. These are precision-turned on CNC machines to maintain concentricity and threading integrity. Surface finishes include natural Brass, nickel plating, tin plating, and silver for enhanced conductivity. These are widely used in electronics, instrumentation, and automotive connectors. Our customization capabilities include custom head styles, overall lengths, and thread combinations.

Copper Jack Screws Copper Jack Screws are selected for EMI shielding and high-conductivity applications. Available in pure Copper (C11000, Cu-ETP) or Copper alloys (C14500, Tellurium Copper), these screws are suitable for use in grounding interfaces, RF shielding compartments, and sensitive signal assemblies. Our Copper Jack Screws feature burr-free machining, uniform plating, and tight tolerances as low as ±0.02 mm. Common finishes include tin plating and bare Copper with passivation. These jack screws meet ASTM B187/B196 standards and are especially preferred in data communication and military-grade assemblies.

Stainless Steel Jack Screws Stainless Steel Jack Screws are known for their corrosion resistance, mechanical strength, and clean appearance. We offer Stainless Steel grades like AISI 303, 304, 316, and 416 in compliance with ASTM A276 and DIN 1.4301/1.4401. These screws are ideally suited for rugged environments including marine, defense, industrial control, and outdoor electronics. All screws undergo thread rolling, polishing, and optional passivation. These are also available with self-locking features or special non-magnetic properties depending on application needs.

Technical Specifications | Thread Types | M2, M2.5, M3, M4, M5, M6, M8; UNC 4-40, 6-32, 8-32 | | Material Grades | Brass (IS 319, CZ121, ASTM B16), Copper (C11000, C14500), Stainless Steel (AISI 303/304/316), Custom Alloys | | Finish Options | Natural, Nickel, Tin, Silver, Zinc Plated, Black Oxide | | Tolerance | ±0.02 mm or as per customer specification | | Turnaround Time | 4–6 Weeks | | Thread Standards | ISO Metric, UNC/UNF, DIN 13, JIS B0205 |

Why Choose Us? With over three decades of global experience, we offer superior communication, competitive pricing, and unmatched flexibility in production timelines. Our team ensures:

- Faster turnaround times

- Customized sizes and finishes

- Global delivery and logistics support

- Private label packaging with logos

- Engineering support and prototyping services

Customer Testimonial “We’ve been sourcing Stainless Steel and Brass Jack Screws from them for 7 years. Their consistency, responsiveness, and ability to meet our special packaging requirements are unmatched. Highly recommend!” — Michael D., Chicago, USA

Glossary of Terms

- Jack Screws: Mechanical fasteners used to mount and secure connectors.

- UNC Threads: Unified National Coarse thread standard, common in USA.

- RoHS Compliance: Restriction of Hazardous Substances directive ensuring material safety.

- CNC Machining: Computer-controlled machining process for precision manufacturing.

- Xenon Testing: Optional UV stability test for plating durability.

Related Terms Jack Screws for Electronics, Precision Threaded Screws, D-sub Connector Screws, RF Grounding Screws, Custom CNC Turned Screws, RoHS Compliant Fasteners, OEM Jack Screws, High Conductivity Copper Screws, Brass electronic hardware, Brass fasteners

CTA: To request a detailed quote or product brochure, please email us or call/WhatsApp us.