Introduction to Stainless Steel Pressed & Stamped Parts

Stainless steel pressed and stamped parts represent a cornerstone of modern manufacturing, providing essential components for industries ranging from automotive and aerospace to medical and electronics. These precision-engineered parts combine the exceptional properties of stainless steel with sophisticated forming techniques to create components that meet the most demanding performance requirements.

This comprehensive guide explores the full spectrum of stainless steel pressed and stamped parts – covering everything from material selection and manufacturing processes to quality control standards and emerging industry trends. Whether you’re an engineer, procurement specialist, or manufacturing professional, this resource provides the essential knowledge needed to understand, source, and utilize these critical components.

What Are Stainless Steel Pressed parts, Stainless Steel pressed components & Stainless Steel Stamped Parts?

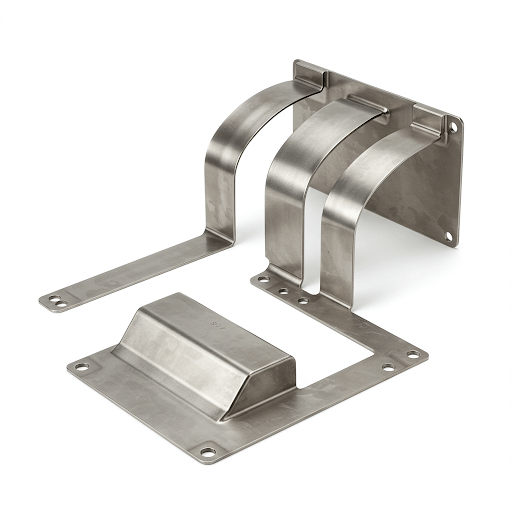

Stainless steel pressed and stamped parts are metal components formed using force-based manufacturing techniques that shape flat sheet metal into specific geometries without adding or removing material. The process involves applying pressure using specialized tools and die sets to transform stainless steel sheets into components with precise dimensions and functional features.

These techniques create components with exceptional consistency, durability, and corrosion resistance while maintaining cost-effectiveness for medium to high-volume production runs. The resulting parts span an incredible range of applications – from simple brackets and fasteners to complex automotive components and sensitive medical devices.

Understanding Stainless Steel Materials

Stainless steel’s unique combination of properties makes it an ideal material for pressed and stamped components. The material’s corrosion resistance, durability, aesthetic appeal, and wide temperature range capabilities provide engineers with versatile options for component design.

Common Stainless Steel Grades for Pressing & Stamping

| Grade | Type | Properties | Common Applications |

|---|---|---|---|

| 304 / 304L | Austenitic | Excellent corrosion resistance, good formability, non-magnetic | Food processing equipment, kitchen components, architectural parts |

| 316 / 316L | Austenitic | Superior corrosion resistance, particularly to chlorides | Marine applications, medical devices, chemical processing equipment |

| 301 | Austenitic | High work hardening rate, excellent strength after forming | Automotive components, railroad cars, aircraft parts |

| 430 | Ferritic | Good formability, moderate corrosion resistance, magnetic | Automotive trim, appliance parts, decorative applications |

| 410 | Martensitic | Heat-treatable, good wear resistance, moderate corrosion resistance | Turbine blades, valve components, fasteners |

| 17-7 PH | Precipitation Hardening | High strength, good fatigue properties, moderate corrosion resistance | Springs, clips, structural components requiring high strength |

Key Material Properties for Pressing & Stamping Applications

- Tensile Strength: Determines the maximum stress a material can withstand before failing. Critical for structural applications.

- Yield Strength: Indicates the stress at which a material begins to deform plastically. Essential for maintaining dimensional integrity.

- Elongation: Measures a material’s ability to stretch without breaking. Higher elongation values typically indicate better formability.

- Work Hardening Rate: The rate at which a material strengthens when deformed. Impacts formability and final part properties.

- Springback: The tendency of a material to partially return to its original shape after forming. Must be accounted for in die design.

- Anisotropy: Variation in mechanical properties along different directions of the sheet. Affects formability and part consistency.

- Surface Finish: Impacts both aesthetic appearance and functional properties like friction and corrosion resistance.

Material Selection Considerations

Selecting the appropriate stainless steel grade for pressing and stamping applications involves balancing multiple factors:

- Performance Requirements: Mechanical strength, corrosion resistance, temperature tolerance, and magnetic properties

- Manufacturing Considerations: Formability, springback characteristics, and tool wear

- Economic Factors: Material cost, availability, and processing requirements

- Regulatory Compliance: Food safety standards, medical device requirements, or environmental regulations

Manufacturing Processes: Pressing & Stamping Techniques

The creation of stainless steel pressed and stamped parts involves a variety of specialized techniques, each suited to particular component requirements. Understanding these processes helps in selecting the optimal approach for specific applications.

Basic Stamping Operations

Blanking

Cutting a flat piece (blank) from sheet metal stock, often as the first step in a multi-stage process. The blank becomes the workpiece for subsequent operations.

Piercing

Creating holes or openings in the workpiece by punching out and removing material. Used for functional features like mounting holes or ventilation openings.

Bending

Forming angular features by deforming the material around a straight axis. Creates flanges, channels, and structural reinforcements.

Drawing

Forming three-dimensional shapes by pulling sheet metal into a die cavity. Creates cups, boxes, and complex contoured shapes.

Coining

Precision stamping that creates fine details by compressing material between dies. Used for creating emblems, texture patterns, and functional features.

Embossing

Creating raised or depressed designs without changing the material thickness. Used for branding, strengthening, or functional purposes.

Advanced Pressing & Stamping Technologies

Progressive Die Stamping

A highly efficient process where multiple stamping operations are performed sequentially as the material moves through a series of stations within a single die. The sheet metal strip advances through the die, with each station performing a specific operation (cutting, bending, forming) until the finished part is produced. Ideal for high-volume production of complex parts.

Transfer Die Stamping

Similar to progressive stamping but uses mechanical means to transfer the workpiece between die stations rather than keeping it attached to the strip. This allows for more complex forming operations and is well-suited for larger parts where strip feeding would be impractical.

Fine Blanking

A precision stamping process that produces parts with exceptional flatness, dimensional accuracy, and smooth cut edges. Uses a triple-action press with additional clamping forces to prevent material deformation during cutting. Ideal for components that require precise tolerances without secondary operations.

Multi-slide Forming (Four-slide)

A specialized forming technique using multiple tools approaching from different directions to create complex bends and forms in a single operation. Particularly effective for small, intricate parts with multiple bends that would be difficult to produce with conventional presses.

Hydroforming

A process using hydraulic pressure to form stainless steel against a die. Particularly valuable for creating complex shapes with uniform wall thickness and minimal material thinning. Can produce parts that would be difficult or impossible with conventional stamping.

Critical Process Parameters

Successful stainless steel stamping depends on precise control of numerous process variables:

| Parameter | Impact on Process | Optimization Strategies |

|---|---|---|

| Press Force | Determines the ability to form material completely; insufficient force leads to incomplete forming | Calculate based on material tensile strength, thickness, and formed area; include safety margin |

| Die Clearance | Affects cut edge quality, burr formation, and tool wear | Typically 5-8% of material thickness for stainless steel; may vary by grade |

| Punch/Die Radius | Influences material flow, thinning, and potential for cracking | Minimum radius typically 0.8-1.0× material thickness; larger for high-strength grades |

| Blank Holder Pressure | Controls material flow and prevents wrinkling during drawing operations | Balance between preventing wrinkles and allowing sufficient material flow |

| Lubrication | Reduces friction, heat generation, and tool wear; improves material flow | Use specialized stamping lubricants formulated for stainless steel |

| Press Speed | Affects material behavior, heat generation, and productivity | Slower speeds often improve part quality but reduce throughput |

Tooling Considerations for Stainless Steel

Stainless steel’s work hardening properties and toughness present unique challenges for tooling design and maintenance:

- Tool Materials: High-speed steel (HSS) for low volumes; carbide, powder metallurgy tools, or chrome-plated tools for higher volumes

- Surface Treatments: PVD coatings, nitriding, or other surface treatments to enhance wear resistance and reduce friction

- Tool Design: Robust construction with proper support and alignment features to handle high forming forces

- Die Maintenance: Regular inspection and maintenance schedules to detect and address wear before it affects part quality

Design Considerations for Stainless Steel Pressed & Stamped Parts

Effective design of stainless steel pressed and stamped parts requires a thorough understanding of both material behavior and manufacturing constraints. Optimizing designs for these processes can significantly impact production efficiency, part quality, and overall costs.

Design Guidelines for Manufacturability

Material Thickness

Recommendation: Maintain uniform thickness wherever possible

Rationale: Variations in thickness complicate forming, increase tool wear, and may create stress concentration points

Minimum Thickness: Typically 0.1mm for stainless steel, though this varies by grade and application

Bend Design

Minimum Bend Radius: Generally 0.8-1.0× material thickness for most stainless grades

Bend Relief: Include cutouts at bend intersections to prevent tearing

Bend Direction: Orient bends perpendicular to the material grain direction when possible

Hole Features

Minimum Hole Diameter: Generally equal to material thickness

Hole Spacing: Maintain minimum distance of 2× material thickness between holes

Edge Distance: Keep holes at least 2× material thickness from edges

Corner Design

Internal Corners: Use radii to prevent stress concentration and cracking

External Corners: Slight radii improve tool life and part handling

Notch Sensitivity: Avoid sharp notches, especially in work-hardening stainless grades

Design for Cost Optimization

- Standardization: Use standard hole sizes, bend angles, and other features when possible

- Material Utilization: Design for optimal material usage to minimize scrap

- Tolerances: Specify the loosest acceptable tolerances to reduce manufacturing costs

- Secondary Operations: Design to minimize or eliminate the need for secondary finishing operations

- Tool Complexity: Simpler part geometries generally require less complex, less expensive tooling

Common Design Pitfalls and Solutions

| Design Issue | Potential Problems | Recommended Solution |

|---|---|---|

| Insufficient bend radius | Material cracking, excessive thinning, increased tool wear | Increase bend radius to at least 0.8× material thickness; more for harder grades |

| Holes too close to bends | Hole deformation, cracking between hole and bend | Position holes at least 2× material thickness plus bend radius from bend line |

| Deep drawing without draft angles | Material tearing, excessive thinning, difficult part removal | Include draft angles of 0.5-3° depending on draw depth |

| Sharp internal corners | Stress concentration, cracking during forming or in service | Design with appropriate internal radii based on material properties |

| Excessively tight tolerances | Increased manufacturing costs, higher rejection rates | Specify tolerances based on actual functional requirements |

| Insufficient material for forming | Incomplete forming, tearing at transitions | Ensure adequate material in the blank for complete forming; consider simulation |

Design for Secondary Operations

Many stainless steel pressed and stamped parts require additional processing to achieve final specifications:

- Deburring: Design with appropriate edge breaks or specify secondary deburring methods

- Surface Finishing: Consider how stamping affects surface finish and subsequent finishing operations

- Welding: Include appropriate features for fixturing and joint preparation if parts will be welded

- Assembly: Incorporate alignment features, self-fixturing designs, or other elements that facilitate assembly

- Passivation: Ensure accessibility for chemical passivation treatments if required

Quality Control & Testing for Stainless Steel Pressed & Stamped Parts

Ensuring the quality and consistency of stainless steel pressed and stamped parts requires a comprehensive approach to inspection, testing, and process control. Effective quality management strategies help manufacturers meet specifications, reduce defects, and deliver reliable components.

Common Quality Issues & Prevention Strategies

| Quality Issue | Possible Causes | Prevention & Detection Methods |

|---|---|---|

| Springback Variation | Material property variations, inconsistent forming pressure | Compensate in die design, implement process controls, measure before/after forming |

| Surface Scratches/Marks | Tool wear, improper handling, debris in dies | Regular tool maintenance, proper material handling procedures, clean working environment |

| Burrs | Worn tooling, improper die clearance, dull cutting edges | Optimize die clearance, regular tool maintenance, deburring operations if necessary |

| Dimensional Variation | Material inconsistency, tool wear, improper setup | SPC monitoring, frequent dimensional verification, material certification |

| Material Thinning | Excessive drawing, insufficient lubrication, improper blank holding | Forming simulation, thickness measurements, optimized process parameters |

| Cracking/Splitting | Excessive deformation, insufficient bend radius, material defects | Material testing, bend radius verification, forming simulation |

| Orange Peel Surface | Coarse grain structure in material, excessive stretching | Material selection, grain size control, controlled forming parameters |

Inspection & Testing Methods

Dimensional Inspection

- Coordinate Measuring Machines (CMM)

- Optical measurement systems

- Laser scanning

- Profile projectors

- Precision gauges and fixtures