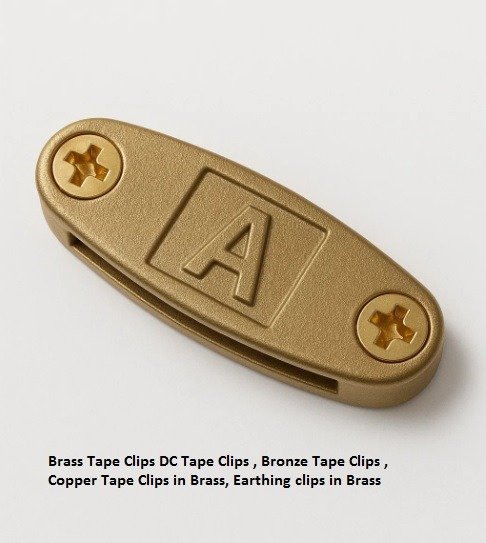

BRASS TAPE CLIPS BRASS DC TAPE CLIPS & BRONZE TAPE CLIPTechnical Specification & Application Guide

Brass and bronze tape clips (also known as DC clips) are essential components in electrical earthing and lightning protection systems. These specialized fasteners provide secure connectivity between copper earthing tapes and various metal structures, ensuring reliable performance in demanding environmental conditions.

Product Overview

Tape clips are precision-engineered from high-quality copper alloys (brass or bronze) to provide:

- Superior Electrical Conductivity: Low-resistance connections for efficient current discharge

- Exceptional Corrosion Resistance: Prolonged operational life in harsh environments

- Mechanical Strength: Secure fastening under physical stress and thermal cycling

- Compatibility: Designed for use with standard copper tape dimensions (25 x 3mm, 25 x 6mm, 50 x 3mm, 50 x 6mm, and 75 x 6mm)

Technical Specifications

Material: High-conductivity brass (CZ121/CW614N) or phosphor bronze (C51000/PB102) Finish: Natural or tin-plated for enhanced corrosion protection Copper Tape Compatibility: 25 x 3mm, 25 x 6mm, 50 x 3mm, 50 x 6mm, 75 x 6mm standard sizes Thread Options: M8, M10, M12 Tensile Strength: >240 N/mm² (brass), >380 N/mm² (bronze) Temperature Range: -40°C to +250°C Compliance: IEC 62561, BS EN 50164, UL 467

Copper Tape Specifications

25 x 3mm:

- Cross-Sectional Area: 75 mm²

- Typical Current Capacity: 14.5 kA

- Recommended Applications: Secondary earthing, small structures

25 x 6mm:

- Cross-Sectional Area: 150 mm²

- Typical Current Capacity: 29 kA

- Recommended Applications: Medium-duty applications, branch conductors

50 x 3mm:

- Cross-Sectional Area: 150 mm²

- Typical Current Capacity: 29 kA

- Recommended Applications: Alternative to 25 x 6, easier to manipulate

50 x 6mm:

- Cross-Sectional Area: 300 mm²

- Typical Current Capacity: 58 kA

- Recommended Applications: Main earthing conductors, lightning down conductors

75 x 6mm:

- Cross-Sectional Area: 450 mm²

- Typical Current Capacity: 87 kA

- Recommended Applications: Heavy-duty applications, primary earth bars

Note: Current capacity based on short-duration fault current ratings at standard temperature rise

Types and Applications

Standard Brass DC Clips:

- Used for general-purpose earthing connections

- Ideal for moderate environmental conditions

- Cost-effective solution for most commercial applications

Bronze Tape Clips:

- Superior corrosion resistance in marine and industrial environments

- Enhanced mechanical strength under vibration and stress

- Recommended for critical infrastructure and harsh exposure conditions

Specialty Configurations:

- DC Clips with inspection windows for visual verification

- Double-bolt versions for high-security connections

- Expansion designs for thermal cycling environments

Installation Best Practices

- Ensure clean contact surfaces free from paint, oxide, or contaminants

- Apply contact aid compound when specified by system design

- Tighten to manufacturer-recommended torque values:

- M8: 12-15 Nm

- M10: 20-25 Nm

- M12: 30-35 Nm

- Verify connection annually as part of routine maintenance

Quality Assurance

Premium tape clips undergo rigorous testing procedures including:

- Salt spray exposure testing (>1000 hours)

- Accelerated corrosion testing

- Current injection testing

- Mechanical pull testing

Application Examples

- Lightning protection systems for buildings and structures

- Earthing networks for telecommunications installations

- Power distribution grounding systems

- Railway electrification earthing

- Industrial facility ground fault protection

- Data center equipotential bonding

Selection Guidance

When selecting tape clips, consider:

- Environmental exposure conditions

- Expected service life requirements

- Copper tape dimensions (ensure compatible clip size)

- Installation accessibility and maintenance

- Relevant compliance standards for your application

For harsh environments with chemical exposure, marine salt conditions, or critical safety applications, bronze clips offer superior performance characteristics despite higher initial cost, providing long-term value through extended service life and reliability.